filmov

tv

How Sensors Keep Bridges From Collapsing (and other structures too)

Показать описание

Infrastructure Instrumentation to save lives and make cool graphs!

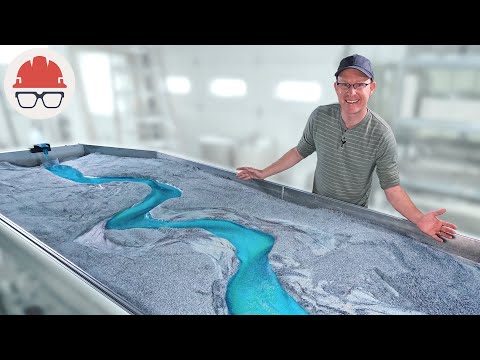

It turns out that plenty of types of infrastructure, especially those that have serious implications for public safety, are equipped with instruments to track their performance over time and even save lives by providing an early warning if something is going wrong. Engineers keep an eye on strain, vibrations, temperature, pressure, tilt, flow rate, and more to make sure that structures behave like they were designed and to keep people safe from disaster.

Practical Engineering is a YouTube channel about infrastructure and the human-made world around us. It is hosted, written, and produced by Grady Hillhouse. We have new videos posted regularly, so please subscribe for updates. If you enjoyed the video, hit that ‘like’ button, give us a comment, or watch another of our videos!

CONNECT WITH ME

____________________________________

SPONSORSHIP INQUIRIES

____________________________________

DISCLAIMER

____________________________________

This is not engineering advice. Everything here is for informational and entertainment purposes only. Contact an engineer licensed to practice in your area if you need professional advice or services. All non-licensed clips used for fair use commentary, criticism, and educational purposes.

SPECIAL THANKS

____________________________________

This video is sponsored by Henson.

Stock video and imagery provided by Getty Images, Shutterstock, Pond5, and Videoblocks.

Tonic and Energy by Elexive is licensed under a Creative Commons Attribution License

Hosted/Written/Produced by Grady Hillhouse

Edited by Wesley Crump

Script Edited by Ralph Crewe

Production Assistance from Josh Lorenz

Graphics by Nebula Studios

It turns out that plenty of types of infrastructure, especially those that have serious implications for public safety, are equipped with instruments to track their performance over time and even save lives by providing an early warning if something is going wrong. Engineers keep an eye on strain, vibrations, temperature, pressure, tilt, flow rate, and more to make sure that structures behave like they were designed and to keep people safe from disaster.

Practical Engineering is a YouTube channel about infrastructure and the human-made world around us. It is hosted, written, and produced by Grady Hillhouse. We have new videos posted regularly, so please subscribe for updates. If you enjoyed the video, hit that ‘like’ button, give us a comment, or watch another of our videos!

CONNECT WITH ME

____________________________________

SPONSORSHIP INQUIRIES

____________________________________

DISCLAIMER

____________________________________

This is not engineering advice. Everything here is for informational and entertainment purposes only. Contact an engineer licensed to practice in your area if you need professional advice or services. All non-licensed clips used for fair use commentary, criticism, and educational purposes.

SPECIAL THANKS

____________________________________

This video is sponsored by Henson.

Stock video and imagery provided by Getty Images, Shutterstock, Pond5, and Videoblocks.

Tonic and Energy by Elexive is licensed under a Creative Commons Attribution License

Hosted/Written/Produced by Grady Hillhouse

Edited by Wesley Crump

Script Edited by Ralph Crewe

Production Assistance from Josh Lorenz

Graphics by Nebula Studios

Комментарии

0:17:08

0:17:08

0:04:55

0:04:55

0:05:14

0:05:14

0:01:57

0:01:57

0:03:22

0:03:22

0:04:10

0:04:10

0:01:42

0:01:42

0:02:37

0:02:37

0:05:47

0:05:47

0:01:36

0:01:36

0:00:41

0:00:41

0:06:22

0:06:22

0:03:01

0:03:01

0:14:51

0:14:51

0:00:29

0:00:29

0:15:24

0:15:24

0:07:22

0:07:22

0:04:11

0:04:11

0:10:09

0:10:09

0:13:02

0:13:02

0:17:48

0:17:48

0:21:52

0:21:52

0:59:36

0:59:36

0:09:28

0:09:28