filmov

tv

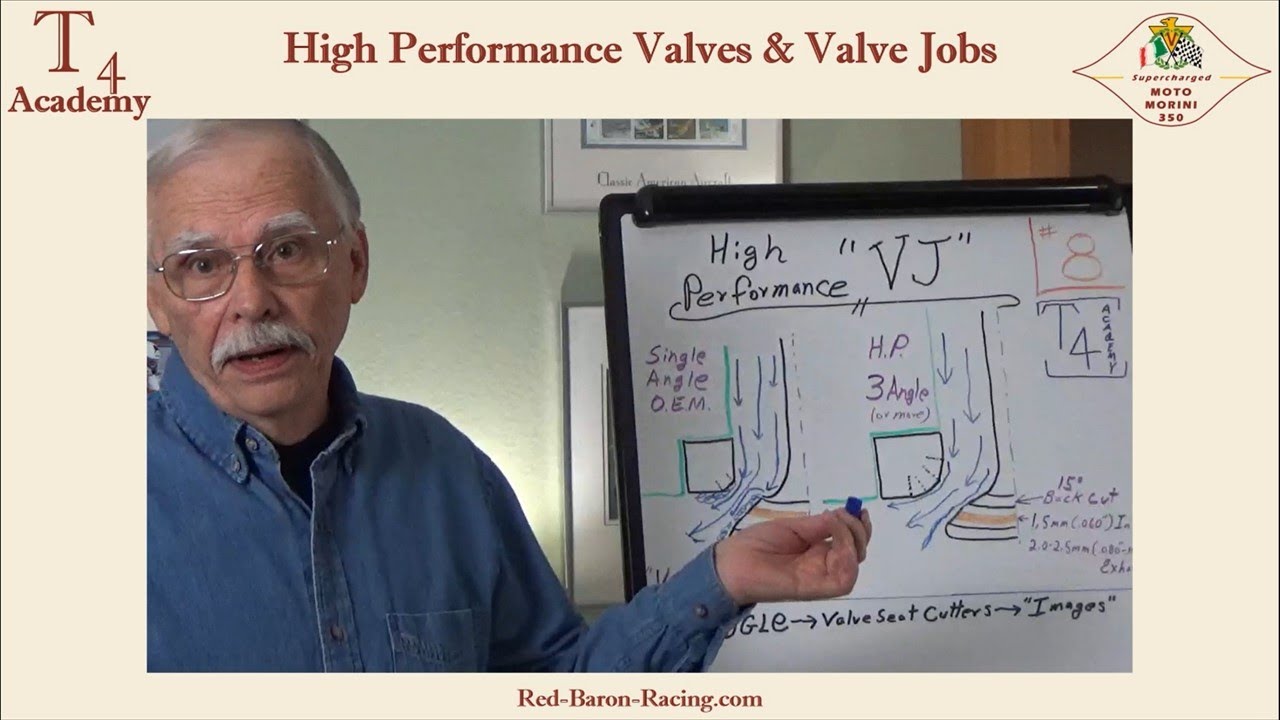

Multi-Angle Valve Job for High Performance

Показать описание

Smitty describes the aerodynamic benefits of multi-angle valve jobs, increasing airflow and therefore horsepower by simply "knockin' off some corners."

Multi-Angle Valve Job for High Performance

5-angle valve job at work 🖐

5 Angle Valve Job

Can A Valve Job Increase Flow On A Set Of Vortec Heads

Renault 21 Turbo - Multi angle seat valve job

Ported LS3 Valve Job

Do you know why it’s called a 3 angle valve job? #hillcountryperformance

If It Can't Breathe It Can't Make Power ? TC 3 Angle Valve Job !

THREE ANGLE VALVE JOB #automobile #dragracing #mechanic #car #viral #air-cooled #welding #motorsport

DIY 3 Angle Valve Job. No Machinery Needed!

Do Your Own 3-Angle Valve Seats!

#shorts Now Offering Five Angle Valve Jobs! Way Better Than @EngineRehab

Performance AMC 360 final 3 angle valve job. Preparation for a leak free Performance valve job.

B58 road to CNC Part 4- Valve job gains?!

gm 250 three angle valve job. bowl hogging for bigger valves.

How to increase the performance by creating 3 angles in the seat of the valves? #shorts #youtube

Vortec Chevy 3 Angle Valve Job, The Old Way.

STEVE TECH EPISODE 5 valve job

HOW TO DO A THREE ANGLE VALVE JOB on a Air-cooled Volkswagen 041 Heads Part Two of Three

Cylinder Heads Pt 2 | DIY 4 Angle Valve Job | #TrackWorthyNewEdge | Chapter 1, Part 2

Predator 212 HEMI head, GEN3 ⭐️ build, ported, polished, multi angle valve job. // Paulskarts.com...

3 angle valve job and lapping #honda #turbohonda #vtec #civic #turbo #b16 #civicsi #bseries #awd

3 ANGLE VALVE JOB-Watch the full video for a hoot of a good laugh

Valve Job Info

Комментарии

0:06:34

0:06:34

0:00:14

0:00:14

0:00:23

0:00:23

0:09:57

0:09:57

0:02:24

0:02:24

0:00:21

0:00:21

0:00:59

0:00:59

0:19:29

0:19:29

0:01:01

0:01:01

0:20:53

0:20:53

0:15:07

0:15:07

0:01:00

0:01:00

0:15:38

0:15:38

0:05:47

0:05:47

0:00:16

0:00:16

0:00:38

0:00:38

0:34:33

0:34:33

0:07:31

0:07:31

0:10:36

0:10:36

0:24:57

0:24:57

0:02:48

0:02:48

0:00:15

0:00:15

0:00:16

0:00:16

0:20:05

0:20:05