filmov

tv

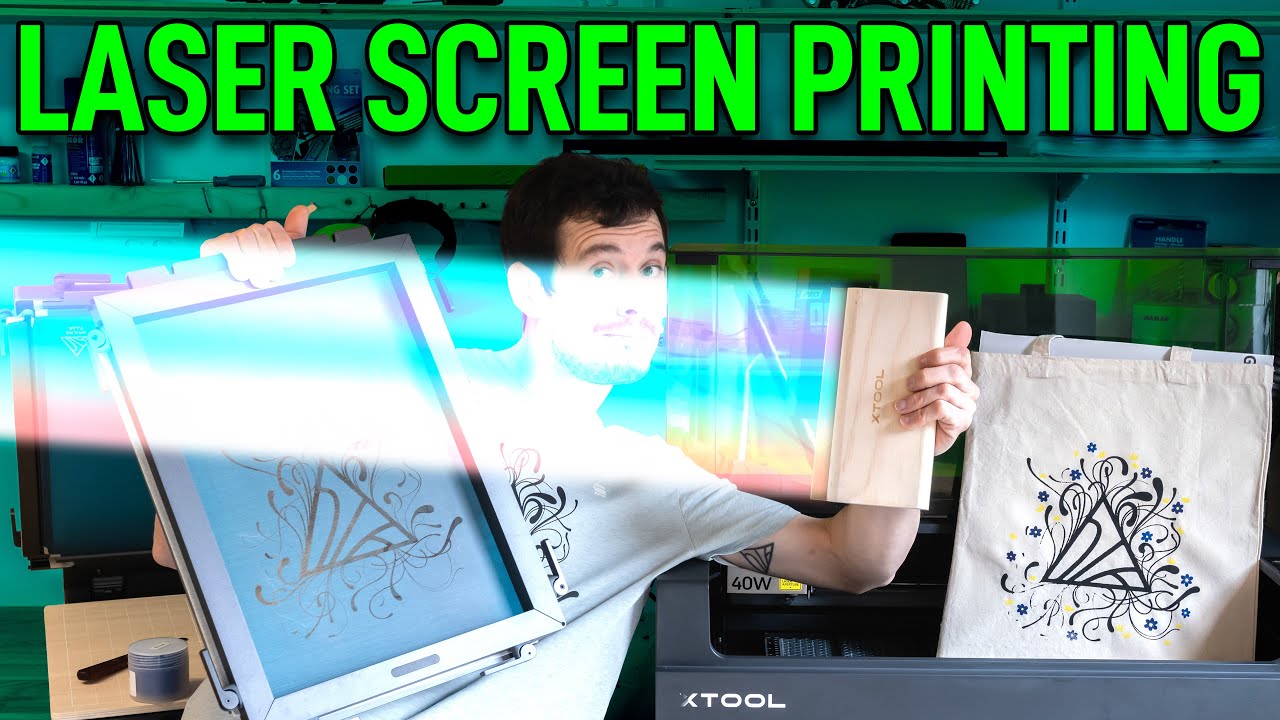

Screen Printing with a Laser Cutter? // xTool S1 40 Watt Laser Cutter + Screen Printer Kit

Показать описание

In a brilliant 'why didn't I think of that' move, xTool has created a system for using their laser cutters to prepare screen printing screens, as well as a standalone screen printer. I thought that sounds awesome, so in this video I'm trying out my new xTool S1 40 watt laser cutter along with that screen printing kit to cut and engrave all sorts of materials!

𝐒𝐡𝐨𝐩𝐩𝐢𝐧𝐠 𝐋𝐢𝐬𝐭*

*Some of these links are connected to affiliate programs that give me a small commission on each sale at no additional cost to you. Thank you for supporting Make Anything!

Thanks to xTool for providing their products for the purpose of review. Opinions expressed in this video are my own.

CHAPTERS

0:00 Intro

1:58 S1 Setup

3:50 Material Tests

12:17 Screen Printer Setup

14:39 Test Screen

16:37 Multicolor Screen Print

22:31 T-shirt Print

24:34 Conclusion

𝐒𝐡𝐨𝐩𝐩𝐢𝐧𝐠 𝐋𝐢𝐬𝐭*

*Some of these links are connected to affiliate programs that give me a small commission on each sale at no additional cost to you. Thank you for supporting Make Anything!

Thanks to xTool for providing their products for the purpose of review. Opinions expressed in this video are my own.

CHAPTERS

0:00 Intro

1:58 S1 Setup

3:50 Material Tests

12:17 Screen Printer Setup

14:39 Test Screen

16:37 Multicolor Screen Print

22:31 T-shirt Print

24:34 Conclusion

World's Fastest Screen Print Starter Kit | xTool

Loving the xTool screen printer and making screens with a laser! #screenprinting

xTool Screen Printer - Effortless Art Painting with Laser

xTool Laser Screen Printing Kit - Fastest Screen Printing Available

Screenprinting WITH LASERS!

Laser Screen Printing: The Future of DIY Tees

XTool Laser Screen Printer - The Future Of Screen Printing?

Screen Printing with Lasers: xTool Screen Printer

Making a unique shadowbox to highlight a first solo flight T shirt!! #pilotlife #pilot

xTool Screen Printer - Reinvent Home Screen Printing Solution with Laser

The xTool Screen Printer - Watch This Before You Buy!

Why I got a Screen Printer, What Can it Do

Screen Printing with a Laser Cutter? // xTool S1 40 Watt Laser Cutter + Screen Printer Kit

Avocado and Laser to Make Screenprinting Screens?? Creality Falcon 2 Pro Laser Cutter Review.

Riley Hopkins Screen Printing Presses w/ Frickin Laser Beams

MiScreen Screen Printing made easy Demo

USING LASER BEAMS for Screen Printing! #shorts

Inkjet Printing and Laser Cutting a Doorplate with xTool M1 Ultra Crafting Machine!

Beginner Screen Print Starter Kit (Final Review!)

Best Emulsion For LTS 8012 Laser-To-Screen | HydroX | Chromaline Screen Print Products

Screen Print a T-shirt with the Speed of Light | xTool Starter Kit

Meet xTool Screen Printer! The First Home Screen Printing Solution with Laser!

i-Image STE II - Computer-to-Screen (CTS) Imaging & Exposure System - M&R Screen Printing

Best Vinyl for Screen Printing with Cricut

Комментарии

0:17:08

0:17:08

0:00:37

0:00:37

0:00:24

0:00:24

0:00:30

0:00:30

0:30:46

0:30:46

0:15:47

0:15:47

0:23:51

0:23:51

0:22:59

0:22:59

0:00:24

0:00:24

0:02:56

0:02:56

0:32:24

0:32:24

0:21:55

0:21:55

0:27:07

0:27:07

0:14:31

0:14:31

0:01:45

0:01:45

0:04:47

0:04:47

0:00:58

0:00:58

0:00:11

0:00:11

0:10:53

0:10:53

0:01:12

0:01:12

0:09:43

0:09:43

1:35:10

1:35:10

0:02:05

0:02:05

0:03:45

0:03:45