filmov

tv

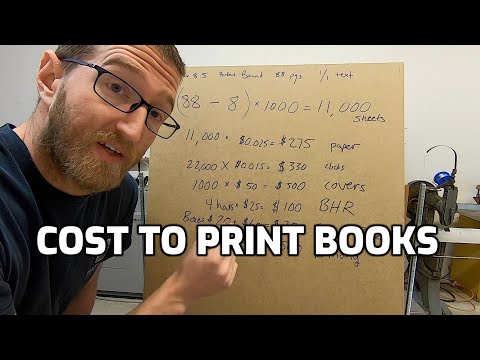

Estimating for Printing Industry and Small Business Spreadsheet Estimator

Показать описание

Keep it Simple. You can estimate for any line of work with simple, free, efficient spreadsheets. This is how I use them to calculate pricing for all kinds of printing. I have several spreadsheets available on my Patreon page. Each tab in the spreadsheet will calculate paper, clicks, BHR, finishing, profit, binding and more. Have fun building your own spreadsheets on either Open Office or Google Sheets. I'm excited.

Estimating for Printing Industry and Small Business Spreadsheet Estimator

Print Estimation Simplified

Mastering Packaging Cost Estimation: The Ultimate Printing Tool contact 9560812408

How to do estimation in 2 Minutes in Indus Print

Estimating and Print Production Management

Printing cost estimation : How to calculate cost of any jobwork

printing ups calculation spreadsheet for Costing estimation

Printpace SAAS based Print Estimating Software for Printing

Adventus & Epson Webinar – Heat-Free Technology: The Future of Printing and Sustainability

Calculate your printing cost easily

Estimating Book Printing

How I calculate my costs for equipment and printing - My Cost Calculator (download available)

Amplify Bottom Line of Your Print Business with 1-Step Print Estimation & Imposition

Layout Planning, Estimation, Costing, Quotation for Offset, Flexo, Corrugation Industry in 1 Minute

Intelligent Print Estimation Software to Grow Your Print Business with Competitive Quotes.

Print Estimating Software - Web to Print MIS - Print Management Information System

How to Calculate Cost Per Print

Printing Cost Estimation for Flexo labels convertors, Quick estimation

Digital Printing Estimation

Estimating the Printing and Binding Cost for Soft Cover Perfect Bound Books

'Printing Cost Estimation Secrets Revealed: How to Slash Your Expenses on Offset Machines!

Learn How to Estimate Printing Business Direct and Indirect Costs Successfully

PrintVis - A Modern Print MIS for Business Central

Printing Automatic Cost Estimator Demo to purchase this sheet contact me on 9560812408

Комментарии

0:18:23

0:18:23

0:10:32

0:10:32

0:12:57

0:12:57

0:04:13

0:04:13

0:02:10

0:02:10

0:08:58

0:08:58

0:01:37

0:01:37

0:00:31

0:00:31

1:15:36

1:15:36

0:04:31

0:04:31

0:05:09

0:05:09

0:12:41

0:12:41

0:09:20

0:09:20

0:00:47

0:00:47

0:02:49

0:02:49

0:00:53

0:00:53

0:03:37

0:03:37

0:06:07

0:06:07

0:15:32

0:15:32

0:18:07

0:18:07

0:15:18

0:15:18

0:10:50

0:10:50

0:32:41

0:32:41

0:06:11

0:06:11