filmov

tv

Made Too Well

Показать описание

Striving to make the best possible product has unforeseen consequences.

20:03 / 21:26

#franlab #frantone #pedal

- Music by Fran Blanche -

20:03 / 21:26

#franlab #frantone #pedal

- Music by Fran Blanche -

Made Too Well

You Know Me Too Well

All Too Well (Taylor's Version)

Taylor Swift - All Too Well (Music Video)

And that made me want to die ~ All too well (10 minutes version) Taylor Swift #taylor #alltoowell

Taylor Swift - All Too Well (10 Minute Version) (Taylor's Version) (From The Vault) (Lyrics)

The actress was too good for the role 💀 #explorepage #explorepost #funnymemes #movies #series #fyp...

Taylor Swift - All Too Well (Lyrics)

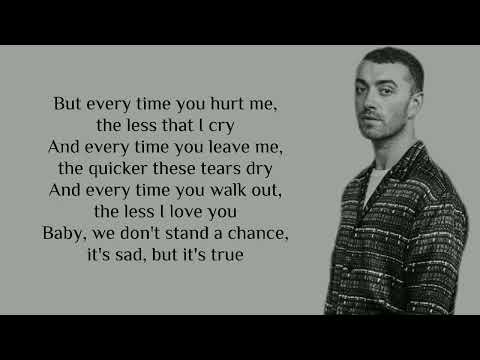

Sam Smith - Too Good At Goodbyes (Lyrics)

‘Completely man-made’: Markets tumble after Fed Chair suggests Trump’s tariffs will cause inflation...

All Too Well by Taylor Swift | cover by Jada Facer ft. Kyson Facer

Uncle Made Time Travel Alcohol & Boy Drink it to Travel Past 💥🤯⁉️⚠️ | Movie Explained in Hindi...

Taylor Swift- All Too Well Lyrics

Maxime Bernier: Trump’s Tariffs, Mass Immigration, and the Oncoming Canadian Revolution

when taylor swift told us about all too well 10 minute version in an Instagram live in 2017

Taylor Swift’s 10-Minute Version of All Too Well Almost Wasn’t Recorded (Extended) | Tonight Show...

Taylor Swift - All Too Well: The Short Film (Behind The Scenes)

Taylor swift - All Too Well (Lyrics)Well maybe we got lost in translation Maybe I asked for too much

Taylor Swift - All Too Well (10 Minute Version) (Türkçe Çeviri)

You got it, dude #shorts

Pacey & Joey | All Too Well

For the peeps who loaf-ed my last loaf 🥲

How tall is Meghan Trainor? #shorts #tall #shorts30

Sam Smith - Too Good at Goodbyes (lyrics)

Комментарии

0:11:43

0:11:43

0:03:54

0:03:54

0:05:30

0:05:30

0:05:22

0:05:22

0:00:59

0:00:59

0:10:12

0:10:12

0:01:00

0:01:00

0:05:30

0:05:30

0:03:24

0:03:24

0:10:47

0:10:47

0:04:54

0:04:54

0:22:29

0:22:29

0:05:30

0:05:30

1:11:53

1:11:53

0:00:27

0:00:27

0:09:39

0:09:39

0:06:57

0:06:57

0:06:01

0:06:01

0:10:11

0:10:11

0:00:15

0:00:15

0:03:55

0:03:55

0:00:21

0:00:21

0:00:15

0:00:15

0:03:22

0:03:22