filmov

tv

Why is SPC (Statistical Process Control) Important?

Показать описание

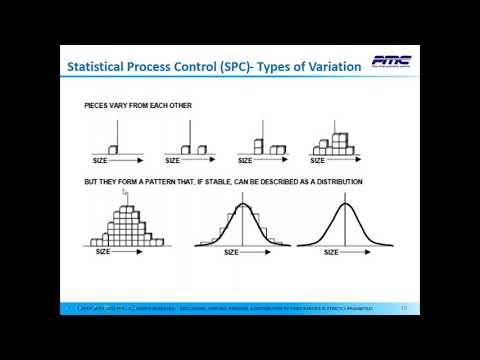

SPC is method of measuring and controlling quality by monitoring the manufacturing process where quality data is collected in the form of product or process measurements or readings from various machines or instrumentation.

SPC (Statistical Process Control) primarily deals with studying variation to improve process performance in any area or process and that SPC focuses on “prevention”, not “detection”, where detection tolerates waste while prevention avoids waste. PMC offers SPC Training that covers Variable and Attribute Control Charts, and Capability Studies along with its applications to manufacturing.

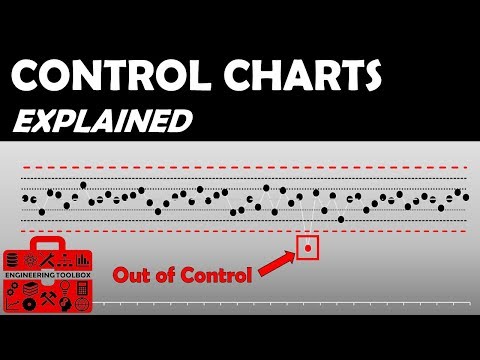

While there are many ways to improve quality and productivity, most of them are variance-reducing procedures of one sort or another. It is the case, however, that strategies for eliminating special-cause variation are almost always completely different from procedures for reducing common-cause variation.

Special-cause variation is the result of some deviation or abnormality in the process. Therefore, when such a cause has been identified, it is almost always possible to remove it. In fact, the responsibility for identifying and removing special causes of variation usually lies with the operator or supervisor-and it is usually carried out at the point of production. Common-cause variation is not a short-term problem. It is almost always the result of very basic, structural “deficiencies” in the process design.

SPC is one type of feedback system. The four elements of the feedback system as shown in the graph are:

The Process

Information About Performance

Action on the Process

Action on the Output

Some of the tools for Controlling and Improving Processes are:

Process Flow Diagrams

Failure Mode and Effects Analysis (FMEA)

Control Plans

Control Charts

Problem Solving Techniques

Design of Experiments

Simulation

Supplier Certification

Preventative Maintenance

Three Stages of Continual Process Improvement Cycle with SPC are:

1. ANALYZE THE PROCESS

What should the process be doing?

Can anything go wrong?

What is the process doing?

Achieve a state of statistical control

Determine Capability

2. MAINTAIN THE PROCESS

Monitor process performance

Detect special cause variation and act upon it

3. IMPROVE THE PROCESS

Change the process to better understand common cause variation

Reduce common cause variation

Additional PMC Quality Services:

PMC provides internal and lead auditor training and certification for:

IATF 16949:2016 – Automotive Quality Management System

Quality Management System - ISO 9001:2015

ISO 14001:2015 – Environmental Management System

Occupational Health and Safety System - ISO 45001:2018

ESD S20.20:2014 – Electro Static Discharge (ESD) Standard

VDA 6.3 – German Automotive Quality Standard

Other PMC Services:

More Information On PMC Can Be Found Below:

313-441-4460

Follow our other social channels:

PMC, Your Partner In Productivity Improvement!

SPC (Statistical Process Control) primarily deals with studying variation to improve process performance in any area or process and that SPC focuses on “prevention”, not “detection”, where detection tolerates waste while prevention avoids waste. PMC offers SPC Training that covers Variable and Attribute Control Charts, and Capability Studies along with its applications to manufacturing.

While there are many ways to improve quality and productivity, most of them are variance-reducing procedures of one sort or another. It is the case, however, that strategies for eliminating special-cause variation are almost always completely different from procedures for reducing common-cause variation.

Special-cause variation is the result of some deviation or abnormality in the process. Therefore, when such a cause has been identified, it is almost always possible to remove it. In fact, the responsibility for identifying and removing special causes of variation usually lies with the operator or supervisor-and it is usually carried out at the point of production. Common-cause variation is not a short-term problem. It is almost always the result of very basic, structural “deficiencies” in the process design.

SPC is one type of feedback system. The four elements of the feedback system as shown in the graph are:

The Process

Information About Performance

Action on the Process

Action on the Output

Some of the tools for Controlling and Improving Processes are:

Process Flow Diagrams

Failure Mode and Effects Analysis (FMEA)

Control Plans

Control Charts

Problem Solving Techniques

Design of Experiments

Simulation

Supplier Certification

Preventative Maintenance

Three Stages of Continual Process Improvement Cycle with SPC are:

1. ANALYZE THE PROCESS

What should the process be doing?

Can anything go wrong?

What is the process doing?

Achieve a state of statistical control

Determine Capability

2. MAINTAIN THE PROCESS

Monitor process performance

Detect special cause variation and act upon it

3. IMPROVE THE PROCESS

Change the process to better understand common cause variation

Reduce common cause variation

Additional PMC Quality Services:

PMC provides internal and lead auditor training and certification for:

IATF 16949:2016 – Automotive Quality Management System

Quality Management System - ISO 9001:2015

ISO 14001:2015 – Environmental Management System

Occupational Health and Safety System - ISO 45001:2018

ESD S20.20:2014 – Electro Static Discharge (ESD) Standard

VDA 6.3 – German Automotive Quality Standard

Other PMC Services:

More Information On PMC Can Be Found Below:

313-441-4460

Follow our other social channels:

PMC, Your Partner In Productivity Improvement!

Комментарии

0:04:39

0:04:39

0:04:03

0:04:03

0:02:09

0:02:09

0:02:59

0:02:59

0:33:24

0:33:24

0:09:23

0:09:23

0:00:33

0:00:33

0:03:23

0:03:23

0:26:22

0:26:22

0:02:06

0:02:06

0:01:21

0:01:21

0:55:43

0:55:43

0:09:44

0:09:44

0:04:24

0:04:24

0:02:39

0:02:39

0:11:43

0:11:43

0:15:57

0:15:57

0:08:49

0:08:49

0:07:30

0:07:30

0:07:01

0:07:01

0:31:30

0:31:30

0:01:24

0:01:24

0:21:05

0:21:05

0:02:45

0:02:45