filmov

tv

Liquid Line Temperature

Показать описание

Bryan goes over the basics of liquid line temperature. He explains how we measure it, what it can tell us, and what appropriate ranges tend to be.

We typically measure liquid line temperature with a temperature clamp outside at the condenser. Normally, the liquid line temperature shouldn't change very much; even in cases when you have exceptionally long line sets or if the liquid line has been routed through hot areas, you shouldn't see much more than a two to three-degree difference throughout. By comparison, the suction line has a lot more variation from start to finish.

The liquid line can't be any colder than the medium to which the condenser is rejecting its heat (the outdoor air). In other words, the liquid line can't be cooler than the outdoor air in a traditional residential split A/C unit. If the liquid line is colder than the outdoor temperature, check to make sure that your probes are in the correct places (e.g., not in direct sunlight).

If you detect a significant temperature difference or if the liquid line is colder than the outdoor air, you may be dealing with a restriction between the condenser and wherever you're measuring. Restrictions may be in the line itself, in the liquid line service valve, or in the liquid line filter-drier. Elevated liquid line temperatures may indicate a restricted condenser coil or overcharge.

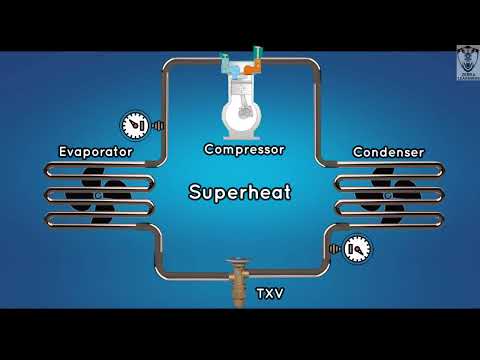

We can determine the appropriate liquid line temperature range by looking at the condensing temperature over ambient (CTOA), which is the difference between the condensing temperature (saturation inside the condenser) and the outdoor ambient temperature. Older systems tend to have higher CTOA, and newer high-efficiency systems tend to have lower CTOA.

Comparing the liquid line temperature to the ambient temperature is called the "approach" method. The absolute highest temperature that the liquid line could be is the CTOA, and the lowest it could be is the outdoor ambient temperature. To find out what our liquid line temperature should be, we also have to look at our subcooling. You can subtract the subcooling from the CTOA to get your ideal liquid line temperature. Of course, there is some guesswork involved in this method.

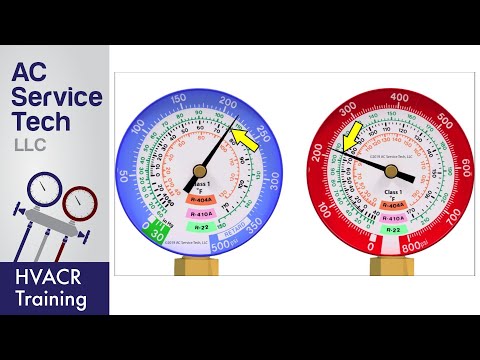

If the liquid line temperature is much higher than expected, then it may be time to connect gauges.

It's also worth noting that refrigeration systems will often have higher CTOA than HVAC systems. However, we're also trying to reduce the condensing temperature to reduce compression ratios and get more efficiency out of our systems.

We typically measure liquid line temperature with a temperature clamp outside at the condenser. Normally, the liquid line temperature shouldn't change very much; even in cases when you have exceptionally long line sets or if the liquid line has been routed through hot areas, you shouldn't see much more than a two to three-degree difference throughout. By comparison, the suction line has a lot more variation from start to finish.

The liquid line can't be any colder than the medium to which the condenser is rejecting its heat (the outdoor air). In other words, the liquid line can't be cooler than the outdoor air in a traditional residential split A/C unit. If the liquid line is colder than the outdoor temperature, check to make sure that your probes are in the correct places (e.g., not in direct sunlight).

If you detect a significant temperature difference or if the liquid line is colder than the outdoor air, you may be dealing with a restriction between the condenser and wherever you're measuring. Restrictions may be in the line itself, in the liquid line service valve, or in the liquid line filter-drier. Elevated liquid line temperatures may indicate a restricted condenser coil or overcharge.

We can determine the appropriate liquid line temperature range by looking at the condensing temperature over ambient (CTOA), which is the difference between the condensing temperature (saturation inside the condenser) and the outdoor ambient temperature. Older systems tend to have higher CTOA, and newer high-efficiency systems tend to have lower CTOA.

Comparing the liquid line temperature to the ambient temperature is called the "approach" method. The absolute highest temperature that the liquid line could be is the CTOA, and the lowest it could be is the outdoor ambient temperature. To find out what our liquid line temperature should be, we also have to look at our subcooling. You can subtract the subcooling from the CTOA to get your ideal liquid line temperature. Of course, there is some guesswork involved in this method.

If the liquid line temperature is much higher than expected, then it may be time to connect gauges.

It's also worth noting that refrigeration systems will often have higher CTOA than HVAC systems. However, we're also trying to reduce the condensing temperature to reduce compression ratios and get more efficiency out of our systems.

Комментарии

0:11:10

0:11:10

0:09:58

0:09:58

0:06:39

0:06:39

0:03:28

0:03:28

0:00:57

0:00:57

0:02:40

0:02:40

0:10:25

0:10:25

0:03:54

0:03:54

0:00:24

0:00:24

0:00:13

0:00:13

0:07:25

0:07:25

0:00:41

0:00:41

0:07:54

0:07:54

0:01:00

0:01:00

0:01:04

0:01:04

0:06:04

0:06:04

0:10:41

0:10:41

0:15:04

0:15:04

0:21:47

0:21:47

0:02:32

0:02:32

0:00:41

0:00:41

0:04:07

0:04:07

0:00:30

0:00:30

0:00:06

0:00:06