filmov

tv

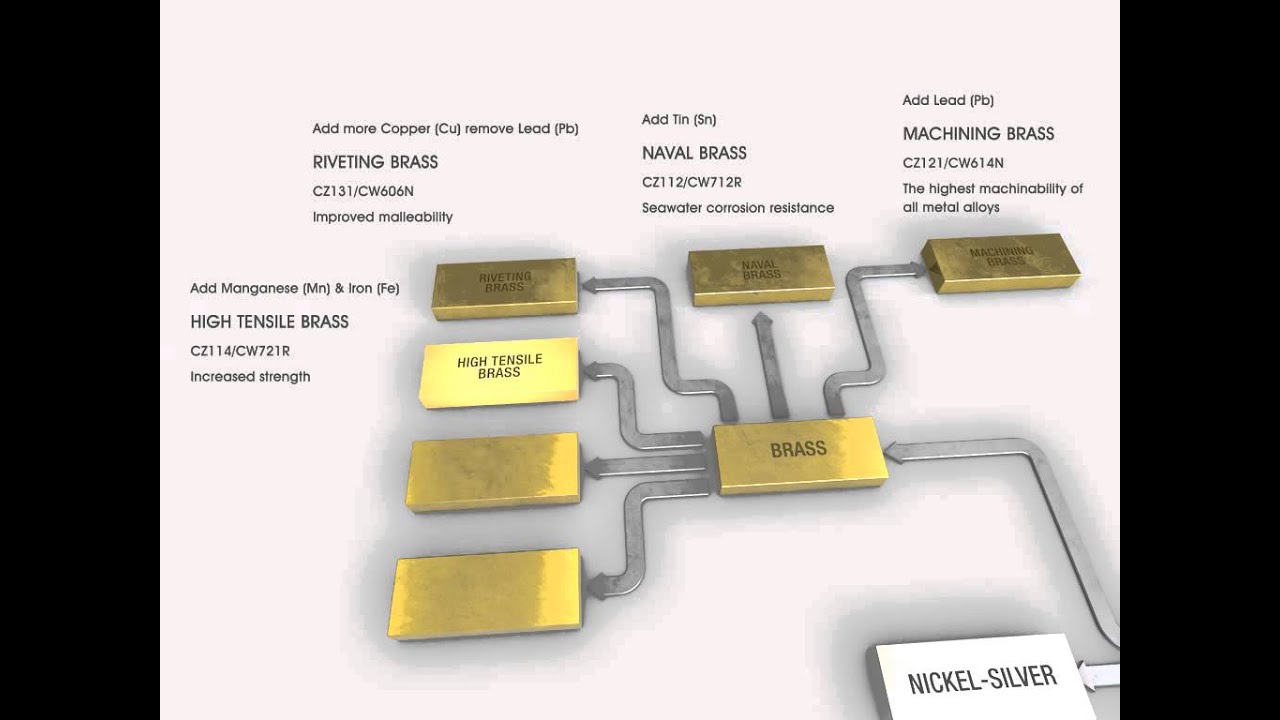

Copper, Brass & Bronze alloys explained

Показать описание

Copper, Brass & Bronze alloys explained

The Difference Between Copper, Brass and Bronze

Copper, Brass & Bronze alloys explained | Copper alloys | Brass | Bronze|properties of copper al...

The Bronze Alloy as Tough as Steel! (almost)

How To Identify Copper, Brass & Bronze

Copper based alloys with composition

The Many Uses of Copper Alloys

Hagerty | Copper, Brass & Bronze Polish | Short tuto

Coating Copper in Brass and Bronze

Joining Brass to Copper with Braze™

Copper Alloy Castings

How to Identify the Differences Between Antique Copper, Bronze & Brass

Copper Brass Silver or Gold - Does it matter what its made of?

What is an alloy of copper and zinc called?

tin bronze foundry,brass/copper alloy lostwax cast company,C90300/90500 tin bronze castings supplies

MIXING METALS - MOLTEN COPPER BRASS & ALUMINIUM TOGETHER - DROP TEST INCLUDED

Brass Bronze Copper Alloy Steel Zinc Plaiting Coating Male And Female Hex Hexagon Head Standoff

Brass vs Copper Jewelry: Which Metal Shines Brighter?

Brazing copper

Melting Copper Wire into Axe - Bronze Casting

Brass Jewelry vs Bronze Jewelry: Which Metal is Right for You?

Pouring an Aluminum Bronze Alloy #casting #bronze #shorts

Copper and copper alloys in railway systems

White Bronze Alloy Experiment (Water Casting)

Комментарии

0:05:21

0:05:21

0:03:25

0:03:25

0:14:54

0:14:54

0:06:36

0:06:36

0:31:01

0:31:01

0:01:22

0:01:22

0:58:17

0:58:17

0:00:21

0:00:21

0:04:48

0:04:48

0:03:34

0:03:34

0:00:25

0:00:25

0:03:02

0:03:02

0:06:10

0:06:10

0:00:18

0:00:18

0:00:35

0:00:35

0:04:17

0:04:17

0:00:32

0:00:32

0:03:45

0:03:45

0:00:30

0:00:30

0:00:59

0:00:59

0:03:44

0:03:44

0:00:16

0:00:16

0:29:30

0:29:30

0:08:01

0:08:01