filmov

tv

Exact Stop vs Constant Velocity in Mach3

Показать описание

In this video, i describe the machine setup differences in Mach 3 using exact stop vs setting up constant velocity. Many folks have problems with corners being rounded in Mach 3 and it is likely due to the CV settings on the General Configuration page.

Exact Stop vs Constant Velocity in Mach3

Exact Stop vs. Constant Velocity

PathPilot Quick Tips: G61 Exact Stop and G64 Constant Velocity Differences

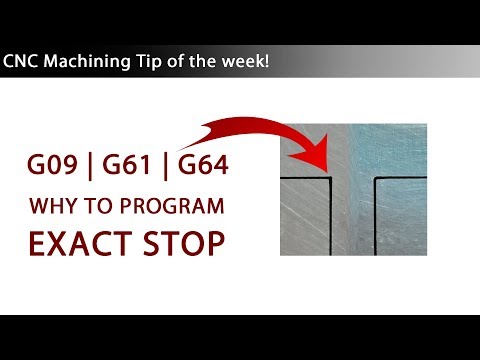

Programming Exact Stop | G09, G61, G64

Constant velocity stops between g1g2 arcs curves problems

Constant Velocity - Don't do it! - CNCnutz Episode 248

The Common MISTAKE Traders Make With Doji Candles #Shorts

Make Smooth running Gcode - CNCnutz Episode 249

Trennjaeger Exact Stop mit Barcode 1

Mach4 Constant Velocity On

Movimento 5 assi senza exact stop

Setup Video Position, Velocity, Acceleration

Mach 3 CV Test 2

Calculating Constant Velocity

Προγραμματισμός Exact Stop | G09, G61, G64

Position/Velocity/Acceleration Part 1: Definitions

Mach4 motion mode bug?

Mach3 speed issues

Misconceptions About Falling Objects

G60 CODE | EXACT STOP FUNCTION IN CNC MACHINE | PRACTICALLY HOW G60 WORKS ?

KinetiC-NC G-Codes cv constant velocity mode G61 G62

Great science teacher risks his life explaining potential and kinetic energy

geneva mechanism || mechanical mechanism🔥📌 #mechanism# #solidworks#engineering#3ddesign@Er_Simmu1014...

Processo v carve positivo e negativo cnc router exact stop estava ativado,

Комментарии

0:06:35

0:06:35

0:05:30

0:05:30

0:00:58

0:00:58

0:05:37

0:05:37

0:01:21

0:01:21

0:13:20

0:13:20

0:00:47

0:00:47

0:28:21

0:28:21

0:00:22

0:00:22

0:00:22

0:00:22

0:00:32

0:00:32

0:04:12

0:04:12

0:00:38

0:00:38

0:05:52

0:05:52

0:04:30

0:04:30

0:07:40

0:07:40

0:05:13

0:05:13

0:00:23

0:00:23

0:03:22

0:03:22

0:04:22

0:04:22

0:02:19

0:02:19

0:03:19

0:03:19

0:00:08

0:00:08

0:21:06

0:21:06