filmov

tv

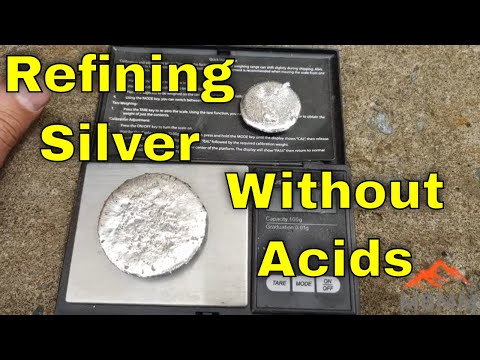

Silver Refining Process Without Acids

Показать описание

In this video, learn how to refine silver jewelry sweeps by smelting and cupelling without the use of acids. The sweeps are separated into a metallic fraction for direct refining with lead by cupelling. The other silver containing material is first smelted down to a metallic button and then further refined to pure silver. At the end of the video the two buttons are combined into one single silver bar.

AFFILIATE LINKS

What's an affiliate link? If you use our link to buy something, MBMM gets a small percentage of the money you spend. This DOES NOT mean you will spend more money using our link, you will spend the SAME AMOUNT of money while also supporting a small business and channel.

Complete Smelting Kits:

Fluxes:

Smelting Supplies:

Furnace Building Supplies:

Underground Mining Equipment:

Filming Equipment:

For more info please email or call:

Phone: 360-595-4445

AFFILIATE LINKS

What's an affiliate link? If you use our link to buy something, MBMM gets a small percentage of the money you spend. This DOES NOT mean you will spend more money using our link, you will spend the SAME AMOUNT of money while also supporting a small business and channel.

Complete Smelting Kits:

Fluxes:

Smelting Supplies:

Furnace Building Supplies:

Underground Mining Equipment:

Filming Equipment:

For more info please email or call:

Phone: 360-595-4445

Silver Refining Process Without Acids

Silver Refining With Household Chemicals NO NITRIC

High Purity Silver Refining (Lye & Sugar Method)

Easy DIY Gold & Silver Refining Process At Home, No Acids. Remove Base Metals By Cupelling MBMM

Refining Silver Using Salt and Iron Nails | How to Refine Silver - Gold Smith Jack

How to refine silver in easy 3 steps | refining silver 2 kg

How to refine Silver - The Complete Silver Chloride Process Tutorial

Refining silver without nitric acid with electrolisis.

QUESTION PAPER DISCUSSION 2024 | CBSE Grade 10-CHEMISTRY|

Refining POUNDS of SILVER!!

Silver refining with nitric acid-time lapse

How to purify 999 silver from scrape?-999 silver refining-Adamjewellery

How to Refine Silver By Nitric Acid | Copper Method | Silver Refining

How and Where to Find Scrap Silver - Identification, Refining With Acid

How To Silver Refining At Home

Refining Sterling Silver Into .99 - .999 Fine Silver (minus silver cell)

Silver Cell gone wrong! Oh NO! #silver #refining

Silver refining and purification process.

Cementing Silver Out of Solution with Copper

High Purity Silver With Drain Cleaner pt1

SILVER REFINING Complete Process plate removal without harsh chemicals VERY EASY 1 of 2

Nitric acid silver refining pt 1

Dissolving sterling silver flatware in nitric acid for refining silver to pure 99.999 pure! #gold

Entire Process of Melting Down Silver Coins, Refining, and Testing to 0.999 Purity

Комментарии

0:13:10

0:13:10

0:34:21

0:34:21

0:13:12

0:13:12

0:06:50

0:06:50

0:06:23

0:06:23

0:14:21

0:14:21

0:10:33

0:10:33

0:03:33

0:03:33

0:49:50

0:49:50

0:07:30

0:07:30

0:00:27

0:00:27

0:15:58

0:15:58

0:08:41

0:08:41

0:13:06

0:13:06

0:04:28

0:04:28

0:14:44

0:14:44

0:00:16

0:00:16

0:00:36

0:00:36

0:00:59

0:00:59

0:41:39

0:41:39

0:37:29

0:37:29

0:00:18

0:00:18

0:00:18

0:00:18

0:23:58

0:23:58