filmov

tv

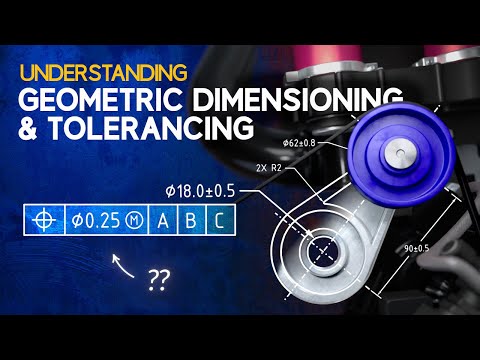

GD&T - Selecting Datum Features

Показать описание

This video shows how to choose datum features with functional GD&T applications. Functional datum features benefit design, manufacturing, and inspection. Non-functional datum features cause stack ups of profile and position tolerance.

GeoTol Inc. is a full-service training and consulting firm on geometric dimensioning and tolerancing. Please visit our website for information regarding onsite training, online training, virtual training, consulting, books, pocket guides, DVD video, leader PowerPoint and model set packages.

GeoTol Inc. is a full-service training and consulting firm on geometric dimensioning and tolerancing. Please visit our website for information regarding onsite training, online training, virtual training, consulting, books, pocket guides, DVD video, leader PowerPoint and model set packages.

GD&T - Selecting Datum Features

GD&T: Choosing Datums

GD&T, Choosing functional vs non-functional datum features

GD&T intro - Qualifying the Datum Features

GD&T example: 2 parts with datums, position, and profile tolerance

Locating Datum Features

GD&T Lesson 4: Datums & Datum Reference Frame

Examples with Datum Features, Datums and True geometric Coun

GD&T Datum Targets Introduction

GD&T: Decoding Datums

Understanding GD&T

GD&T Choosing Datums II

Datums, Datum Features, and Datum Simulators - Oh My!

Common Datum Features

Datums in GD&T

GD&T - everything about datums, MMC primary, MMC secondary, MMC tertiary etc. How to select datu...

Everything about datums - GD&T Part 3 - How to select datums and datum targets?

Functional Datum Features Episode 1 (Spring 2025)

GD&T Q&A: Composite vs Two Single Segment Position, Single Datum Reference.

Everything about datums - 1 , GD&T Part 2 - How to select datums? definitions and representation

Inner and Outer Diameter Datum Features

Common GD&T Student Questions: A Pattern of Holes as a Datum Feature

Reliable Datum Features

Datums in GD&T #tolerance #GD&T #Datum

Комментарии

0:12:57

0:12:57

0:09:20

0:09:20

0:07:49

0:07:49

0:05:29

0:05:29

0:05:07

0:05:07

0:04:47

0:04:47

0:26:16

0:26:16

0:01:26

0:01:26

0:02:50

0:02:50

0:05:28

0:05:28

0:29:32

0:29:32

0:13:51

0:13:51

0:08:16

0:08:16

0:01:54

0:01:54

0:07:43

0:07:43

0:08:53

0:08:53

0:09:17

0:09:17

0:30:43

0:30:43

0:06:02

0:06:02

0:07:55

0:07:55

0:07:04

0:07:04

0:09:30

0:09:30

0:10:12

0:10:12

0:01:00

0:01:00