filmov

tv

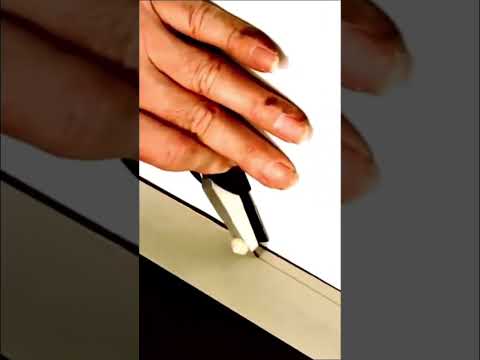

Let's Make a Scribing Tool!

Показать описание

This episode on Blondihacks, I’m making a scriber! Exclusive videos, drawings, models & plans available on Patreon!

Here are links for many of the tools that you see me using:

(I earn small commissions on these links)

Want more content like this? Try these places:

As an Amazon Associate, I earn from qualifying purchases.

Here are links for many of the tools that you see me using:

(I earn small commissions on these links)

Want more content like this? Try these places:

As an Amazon Associate, I earn from qualifying purchases.

Let's Make a Scribing Tool!

Let us describe how we used the Profiler+ to scribe this side gable. How would you do it? #diy

Scribe like a PRO, kitchens, bedrooms, wardrobes, DIY & more #diy #carpentry #howto #woodwork #t...

Making a scribing tool

Scribing made simple ✏️

How to scribe fitted furniture

Make every detail count with the Scribe tool from General Tools 🤝

Special Line Maker ##❗❗

Saker Multi-function Scribing Tool #shorts #newvideo #technogamerz #meta #technology #inventions

Adjustable scribing tool in 20 seconds short

PERFECT scribes every time!

#tracer #carpenter #tools #toolsofthetrade #diy #scribe #proscribe #fyp

How To Temporarily Affix Workpieces When Scribing #trend #scribing #woodworking

How to Scribe The easy way, DIY, Carpentry, Woodwork #doityourself #diy #carpentry #howto #tools #fy

Let's Make a TAP FOLLOWER!

‼️Scribing tip to get you out of a pickle -tips and tricks #shorts

DIY scribing tool for the wheel arch #shorts

Profiler+ The Ultimate Scribing Tool Contour Gauge

Scribing made easy in three simple steps 🤝

SCRIBING TIP: Scribe like a PRO. #diytips #woodworkingtips #woodworking

Multifunctional Woodworking Scribing Tools #woodworking_tools #constructiontools

Standard cutting and scribing tool- Good tools and machinery make work easy

The best way to install scribe on cabinets

Just scribing along

Комментарии

0:19:15

0:19:15

0:00:41

0:00:41

0:00:39

0:00:39

0:13:32

0:13:32

0:00:12

0:00:12

0:00:49

0:00:49

0:00:18

0:00:18

0:00:18

0:00:18

0:00:11

0:00:11

0:00:23

0:00:23

0:01:00

0:01:00

0:00:13

0:00:13

0:00:50

0:00:50

0:00:14

0:00:14

0:23:56

0:23:56

0:00:15

0:00:15

0:00:40

0:00:40

0:00:44

0:00:44

0:00:17

0:00:17

0:00:47

0:00:47

0:00:59

0:00:59

0:00:09

0:00:09

0:00:45

0:00:45

0:00:14

0:00:14