filmov

tv

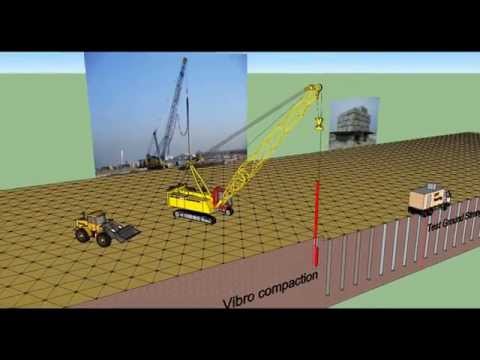

Vibro Compaction ll Under Ground Soil Compaction

Показать описание

Vibro compaction is a ground improvement technique that densifies clean, cohesionless granular soils with a downhole vibrator. It's a technique first developed by Keller in the 1930s that we've used on thousands of projects since.

Common uses

Reduce foundation settlement

Increase bearing capacity, allowing reduction in footing size

Increasing stiffness

Increasing shear strength

Reduce permeability

Mitigate potential for liquefaction

Provide slope stabilization

Process

The vibrator is typically hung from a crane and lowered vertically into the soil under its own weight and vibrations. Penetration is usually helped by water jets integrated into the vibrator assembly. After reaching the bottom of the treatment zone, the soils are densified as the vibrator is raised in lifts. During vibro compaction, clean sand backfill is typically added at the ground surface to compensate for the decrease in soil volume from the densification process. The vibratory energy reduces the inter-granular forces between the soil particles, allowing them to move into a denser configuration, typically reaching a relative density of 70 to 85%. The treated soils have increased density, friction angle and stiffness. Compaction is achieved above and below the water table.

Common uses

Reduce foundation settlement

Increase bearing capacity, allowing reduction in footing size

Increasing stiffness

Increasing shear strength

Reduce permeability

Mitigate potential for liquefaction

Provide slope stabilization

Process

The vibrator is typically hung from a crane and lowered vertically into the soil under its own weight and vibrations. Penetration is usually helped by water jets integrated into the vibrator assembly. After reaching the bottom of the treatment zone, the soils are densified as the vibrator is raised in lifts. During vibro compaction, clean sand backfill is typically added at the ground surface to compensate for the decrease in soil volume from the densification process. The vibratory energy reduces the inter-granular forces between the soil particles, allowing them to move into a denser configuration, typically reaching a relative density of 70 to 85%. The treated soils have increased density, friction angle and stiffness. Compaction is achieved above and below the water table.

0:02:26

0:02:26

0:01:53

0:01:53

0:00:30

0:00:30

0:00:15

0:00:15

0:00:11

0:00:11

0:00:16

0:00:16

0:02:01

0:02:01

0:00:41

0:00:41

0:00:15

0:00:15

0:00:23

0:00:23

0:00:32

0:00:32

0:03:02

0:03:02

0:02:04

0:02:04

0:03:22

0:03:22

0:00:12

0:00:12

0:00:32

0:00:32

1:17:55

1:17:55

0:00:25

0:00:25

0:01:15

0:01:15

0:39:13

0:39:13

0:00:16

0:00:16

0:00:15

0:00:15

0:00:15

0:00:15

0:00:33

0:00:33