filmov

tv

How to Attach Heat Pipes into an Assembly

Показать описание

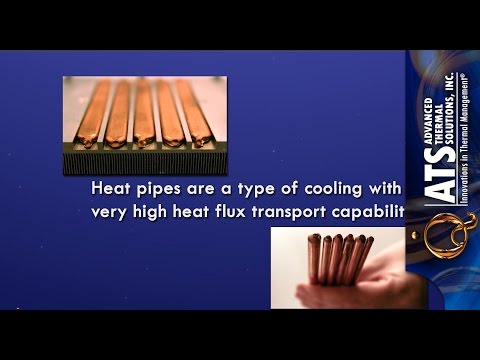

ATS engineer Greg is in the lab today to discuss the ways to attach heat pipes to an assembly and the processes needed for each option.

Advanced Thermal Solutions, Inc.

A leading-edge engineering and manufacturing company focused on the thermal management of electronics.

Service, Products and Training

• Cooling Solutions – From Chip to System

• Mechanical Packaging and Design

• Design Services

• Air and Liquid Cooling Solutions

• Rapid Prototyping

• Custom Heat Sink Design

• Research Grade Thermal Instruments

• Engineering Training

• State-of-the-art Experimental Laboratories

• Qpedia Thermal eMagazine

Advanced Thermal Solutions, Inc.

A leading-edge engineering and manufacturing company focused on the thermal management of electronics.

Service, Products and Training

• Cooling Solutions – From Chip to System

• Mechanical Packaging and Design

• Design Services

• Air and Liquid Cooling Solutions

• Rapid Prototyping

• Custom Heat Sink Design

• Research Grade Thermal Instruments

• Engineering Training

• State-of-the-art Experimental Laboratories

• Qpedia Thermal eMagazine

How to Attach Heat Pipes into an Assembly

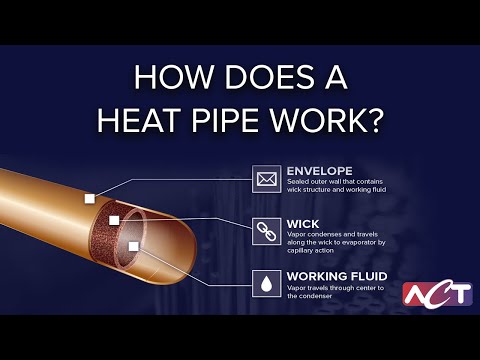

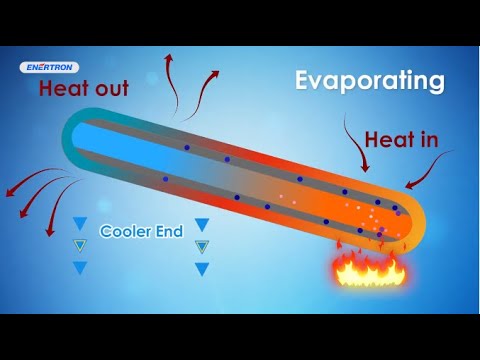

Heat Pipe Basics and Demonstration on How a Heat Pipe Works

How To Install Heat Tape To Your Pipes

Soldering heat sink with heat pipes

MateBook X Pro Mods: Adding Heatpipes (READ DESCRIPTION)

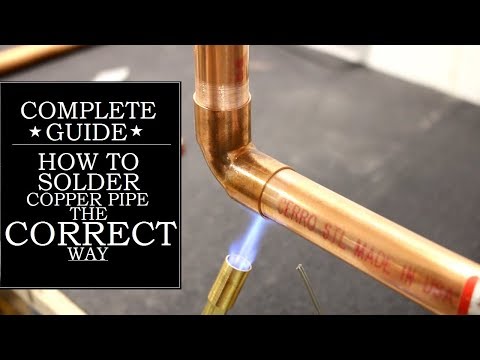

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

The production of be quiet! CPU coolers, part 1: heat pipes

Just How Good Are Heat Pipes Anyway? - DIYson Lamp Build Log #10

How To Install Desktop Cpu Cooler With Heat pipes

HOW TO INSULATE PIPES - Plumbing Tips

Heat Pipe Overview and Explanation

Effective Thermal Conductivity of a Heat Pipe

Electronics tutorial - HEAT PIPES

How to Connect Floor Heating Pipes to the Manifold

How to PREVENT Pipes Freezing in your House or RV - HEAT TAPE

How To Solder Copper Pipe (Complete Guide) Plumbing 101

What's Inside the Worlds' Fastest Heat Conductor?

Volume 1: Heat Pipe Basics 101

Guide: How To Lay Underfloor Heating

CUTTING INTO LIVE CENTRAL HEATING PIPES to fit RADIATOR without draining the system. Plumbing trick

How To Choose a Heat Pipe In 3 Steps

ATS Heat Pipe Line Expansion

How Freeze Protection Cables Can Save Your Pipes - Gear Up With Gregg's

ATS Round Heat Pipe Bending Tools

Комментарии

0:08:13

0:08:13

0:02:16

0:02:16

0:05:15

0:05:15

0:00:23

0:00:23

0:02:01

0:02:01

0:05:05

0:05:05

0:02:54

0:02:54

0:28:41

0:28:41

0:07:26

0:07:26

0:06:45

0:06:45

0:04:49

0:04:49

0:08:47

0:08:47

0:18:47

0:18:47

0:05:03

0:05:03

0:05:54

0:05:54

0:05:54

0:05:54

0:08:29

0:08:29

0:04:36

0:04:36

0:04:44

0:04:44

0:06:39

0:06:39

0:01:52

0:01:52

0:01:25

0:01:25

0:07:55

0:07:55

0:02:33

0:02:33