filmov

tv

How to Use Rockler Deluxe Panel Clamps

Показать описание

Flat panels and flush joints are easy to achieve with our Deluxe Panel Clamps to keep things in line. Each clamp sandwiches your panel between two rigid steel cauls, forcing the joints flush and ensuring flat results. This saves you loads of sanding time, and ensures a nice, level surface without dips and high spots. Thoughtfully engineered from thick steel with scissor-action couplers that apply pressure from all sides, they're perfect for gluing up table tops, wide door panels and thick bench tops. With no bowing under pressure, there is no need to stagger your clamps top and bottom. The clamps are easily adjusted for stock up to 3'' thick and can clamp a panel up to 36'' wide. Buy as many as you need—two is a great starting point.

How to Use Rockler Deluxe Panel Clamps

Rockler Panel Clamps Tool Review by Fort Orange Woodworking

Rockler Mini Deluxe Panel Clamps

Making Flat Wood Panels with New Deluxe Panel Clamps

Installing European Hinges - JIG IT Concealed Hinge Jig

Ditch The Rockler Panel Clamps - A Way Better Solution For Glue Ups

Rockler Mini Panel Clamps

Best Clamps for Making a DIY Cutting Board

Rockler Mini Deluxe Panel Clamps

Are the Rockler Panel Clamps really worth it? $$$

How To TRULY Understand What A Parallel Clamp Can Do | The Wood Whisperer

TOP 10 Most Popular Wood Clamps

Don't sweat over glue drips, because it pops right off Rockler’s Deluxe Panel Clamps.

Rockler Deluxe Drawer Pull JIG IT Assembly | Glass Impressions

Don't Miss These 2022 New Woodworking Tools!

Rockler Deluxe Drawer Pull JIG IT Demo | Glass Impressions

Rockler Panel Clamps. Assembly and Demonstration

New Mini Deluxe Panel Clamps 2 pack! Only at Rockler #clamp #glue #shorts #woodworking #shortsvideo

Hanging @rockler mini deluxe panel clamps

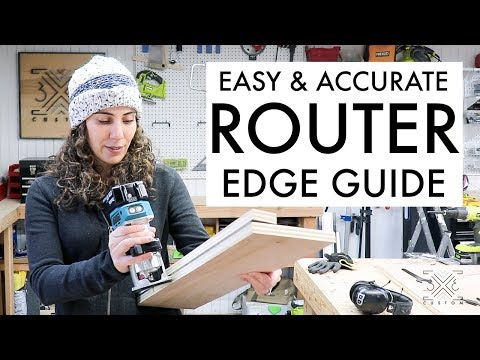

Easy and Accurate Router Edge Guide // Woodworking Jig // Great for Dados and Grooves

How to use the Rockler JIG IT Hinge Drilling Guide

Easiest Way to Install European Cabinet Hinges | Concealed Hinge Drilling System

Opening the box of @rockler mini deluxe panel clamps that we won at Workbench Conference!

Cutting Board - Part 2

Комментарии

0:02:40

0:02:40

0:09:25

0:09:25

0:10:22

0:10:22

0:04:52

0:04:52

0:02:14

0:02:14

0:08:21

0:08:21

0:01:10

0:01:10

0:08:16

0:08:16

0:10:22

0:10:22

0:24:43

0:24:43

0:13:56

0:13:56

0:07:17

0:07:17

0:00:17

0:00:17

0:01:08

0:01:08

0:05:09

0:05:09

0:02:31

0:02:31

0:07:45

0:07:45

0:00:26

0:00:26

0:00:32

0:00:32

0:04:46

0:04:46

0:06:03

0:06:03

0:02:09

0:02:09

0:00:29

0:00:29

0:00:49

0:00:49