filmov

tv

Casting Bronze Dagger. Centurion. Aluminum bronze

Показать описание

The Bronze Age is a historical period characterized by the use of bronze. A lot of things including a weapon were cast of this beautiful metal - bronze. I want to cast aluminum bronze dagger. Sure, aluminum bronze wasn't used that time but classic tin bronze has very similar mechanical characteristics. Nowadays, tin is pretty expensive, so aluminum is a good alternative. The most important is to use hard metal and aluminum bronze is really hard! One of the hardest bronzes.

My other videos:

My other videos:

Casting Bronze Dagger. Centurion. Aluminum bronze

Making Aluminum Bronze Dagger │Casting Dagger

Bronze sword casting. Legionary. Aluminum bronze casting

Bronze dagger casting

My Wife Sharpens the Aluminum Bronze Knife

Casting A HUGE Centurion Sword From SODA CANS - FOR HONOR Sword Making

Casting an Aluminum 'Bronze Age' Sword with Improved Vertical Casting for a Better Surface...

Huge aluminum casting - 4 risers. Hanger

Cast Bronze Dagger Part 2 (Dagger Casting)

Casting The Simple Dagger From Immortal Unchained - How To Replicate Weapons

Casting The Valorant Act III Ruin Dagger - Backyard Metal Casting

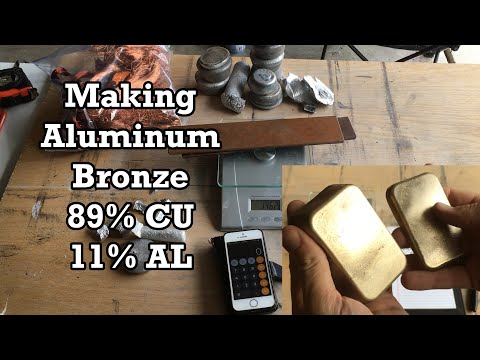

Making Aluminum Bronze (Part 1): Melting Copper and Aluminum - Looks like GOLD!

Making Aluminum Bronze

Lost Foam Bronze Knife Casting (Beginner Casting)

CASTING AN ALUMINUM-BRONZE HAMMER!! *PART ONE*

Casting daggers from MOLTEN Bronze

Casting a sword out of aluminum cable. Trash to treasure . Forging a gladius sword

Lone wolf dagger - Wolf emblem - Aluminum Bronze - Copper - Devil Forge - Metal Melting #DevilForge

Casting A REAL MINECRAFT Pickaxe In Solid Metal - Aluminum Sand Casting From Scrap

Casting Bilbo's 'STING' Sword From Lord Of The Rings & The Hobbit - Sword Making...

Casting DOUBLE MINI Axes From Warhammer 40K - Aluminum Bronze Art From Scrap

Cast Bronze Dagger Part 4 (Pins)

Aluminum Casting A Kubotan | FULL Sand Casting Process From Scrap Metal

Making an Aluminum Bronze Mandalorian Sword #Mandalorian #Sword #DevilForge

Комментарии

0:12:42

0:12:42

0:11:02

0:11:02

0:07:37

0:07:37

0:07:32

0:07:32

0:15:27

0:15:27

0:10:46

0:10:46

0:14:16

0:14:16

0:06:59

0:06:59

0:06:52

0:06:52

0:11:44

0:11:44

0:10:13

0:10:13

0:11:34

0:11:34

0:03:36

0:03:36

0:03:00

0:03:00

0:03:46

0:03:46

0:09:01

0:09:01

0:11:12

0:11:12

0:13:37

0:13:37

0:10:12

0:10:12

0:10:56

0:10:56

0:11:17

0:11:17

0:07:51

0:07:51

0:10:36

0:10:36

0:12:20

0:12:20