filmov

tv

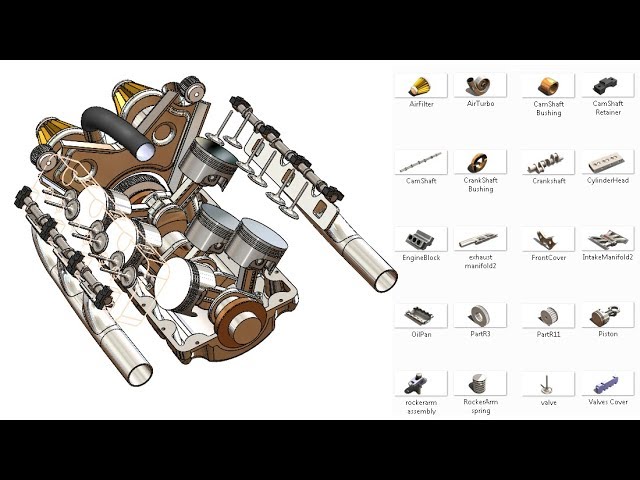

SolidWorks RE Tutorial #320 : Car Engine complete video (2 turbo V6) - (advanced assembly)

Показать описание

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

All dimensions are in mm/g/s/ISO - Based on true dimensioning.

---------------------------------------------------------------------------------------------

Rating, commenting, subscribing and sharing are always appreciated!!

----------------------------------------------------------------------------------------------

The uploading of tutorials is based on an accumulated studied plan!

----------------------------------------------------------------------------------------------

New to SolidWorks?! Recommended to watch my earlier uploads.

----------------------------------------------------------------------------------------------

I will be thankful to you for replying whom are in need.

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Hello & Welcome to SolidWorks Tutorial Channel

This channel is dealing with EVERYTHING about SolidWorks aims to make the viewer a professional SolidWorks user! & to be helpful !

This Channel beside Tutorials Engineer contain topics about:

- SolidWorks Beginners Tutorials

- SolidWorks Sketching

- SolidWorks Surface

- SolidWorks Weldments

- SolidWorks Assembly

- SolidWorks Drawing

- SolidWorks Sheet Metal

- SolidWorks Mold Design

- SolidWorks Simulation

- SolidWorks Motion

And MORE

►►►SUBSCRIBE ?!◄◄◄

-------------------------------------------------------------------------------------------

GO PROFIST ...BE SOLIDWORKIST ◄ suggested words!

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

----------------------------------------------------------------------------------------

★------ ART ENGINEERING CREATIVITY ------★

----------------------------------------------------------------------------------------

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Warm Thanks to them who supported and subscribed our channel in our very early start... All are nice but you are special!!

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

Viewers can contribute translated titles, descriptions, and subtitles/CC (with different languages)

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

OTHERS:

TO BE FILLED

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

■ if you feel want to give something in back : the minimum : Rate, comment, subscribe & share!!

Комментарии

3:44:27

3:44:27

3:44:27

3:44:27

0:00:11

0:00:11

0:00:12

0:00:12

3:49:31

3:49:31

0:00:21

0:00:21

0:05:39

0:05:39

0:01:18

0:01:18

0:00:46

0:00:46

0:00:37

0:00:37

0:00:06

0:00:06

0:02:49

0:02:49

4:04:00

4:04:00

0:40:14

0:40:14

3:44:27

3:44:27

0:00:59

0:00:59

0:00:15

0:00:15

0:00:54

0:00:54

0:18:38

0:18:38

0:00:36

0:00:36

0:25:09

0:25:09

0:26:12

0:26:12

2:58:30

2:58:30

0:10:18

0:10:18