filmov

tv

HYDRAULIC PRESS VS TITANIUM AND STEEL BOLT, WHICH IS STRONGER

Показать описание

We will test the strength of titanium bolts from a spaceship with a hydraulic press. Which bolt is stronger titanium or steel

HIDRAULIC PRESS VS TITANIUM

HYDRAULIC PRESS VS TITANIUM AND CARBON FIBER PIPE

STEEL RING VS TUNGSTEN RING VS TITANIUM RING #hidraulicpress #ring

HYDRAULIC PRESS VS TITANIUM AND STEEL ARMOR

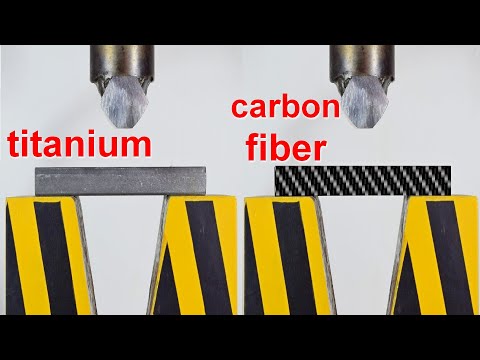

HYDRAULIC PRESS vs TITANIUM AND CARBON FIBER, BENDING TEST

Titanium VS Carbon Fiber Under Hydraulic Press 😮 #viral

HYDRAULIC PRESS VS TITANIUM AND STEEL BOLT, WHICH IS STRONGER

HYDRAULIC PRESS VS TITANIUM BOLTS

HYDRAULIC PRESS VS TITANIUM AND CARBON FIBER, BENDING TEST

How Strong is Titanium? Hydraulic Press Test!

HYDRAULIC PRESS VS KNIVES, EXPENSIVE AND CHEAP

HYDRAULIC PRESS VS STEEL AND TITANIUM

HYDRAULIC PRESS vs TITANIUM AND OBSIDIAN

HYDRAULIC PRESS VS TITANIUM BOLTS, ALIEXPRESS AND SPACE SHUTTLE

HYDRAULIC PRESS VS TITANIUM BOLT burst test

HYDRAULIC PRESS VS TITANIUM AND GLASS

500 TON HYDRAULIC PRESS VS VERY HARD OBJECTS

Which is the strongest ring material? Hydraulic press test! #tungsten #hydraulicpress #crushing

Titanium vs Aluminium vs Brass eggs VS Hydraulic Press 🥚 #hydraulicpress #crushing #satisfying

HYDRAULIC PRESS VS TITANIUM ARMOR

HYDRAULIC PRESS VS TITAN AND RUPERT'S DROP

HYDRAULIC PRESS VS STRONGEST HUMAN BONES 🤯 WHO WILL WIN 💥 #shorts #usa #shortfeed

Deep frozen hammer VS. hydraulic press! #shorts

World’s *STRONGEST* Objects vs Hydraulic Press! (CRAZY)

Комментарии

0:03:30

0:03:30

0:12:03

0:12:03

0:00:43

0:00:43

0:08:42

0:08:42

0:10:59

0:10:59

0:00:38

0:00:38

0:04:48

0:04:48

0:08:45

0:08:45

0:07:46

0:07:46

0:12:11

0:12:11

0:08:24

0:08:24

0:11:55

0:11:55

0:06:40

0:06:40

0:08:02

0:08:02

0:09:59

0:09:59

0:05:00

0:05:00

0:09:02

0:09:02

0:01:01

0:01:01

0:00:16

0:00:16

0:08:37

0:08:37

0:03:25

0:03:25

0:00:58

0:00:58

0:00:13

0:00:13

0:14:08

0:14:08