filmov

tv

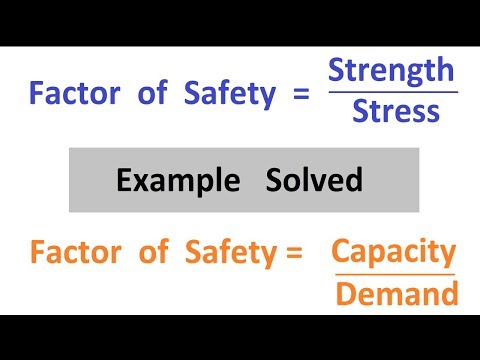

Factor of Safety

Показать описание

This mechanics of materials tutorial goes over the factor of safety, an important topic in mechanics of materials and structural analysis / design.

If you found this video helpful, please consider supporting my work on Patreon:

Looking for more mechanics of material tutorials? Check out all of the videos that I made:

Looking for software? I highly recommend checking out SkyCiv. They make a full suite of online structural analysis software and tools that are useful for both students and professionals, including calculators for beams, trusses, frames, moment of inertia and more. It’s great for checking your work:

Lastly, don’t forget to subscribe on YouTube and join the Engineer4Free mail list:

Thanks for watching, I hope it helps!

If you found this video helpful, please consider supporting my work on Patreon:

Looking for more mechanics of material tutorials? Check out all of the videos that I made:

Looking for software? I highly recommend checking out SkyCiv. They make a full suite of online structural analysis software and tools that are useful for both students and professionals, including calculators for beams, trusses, frames, moment of inertia and more. It’s great for checking your work:

Lastly, don’t forget to subscribe on YouTube and join the Engineer4Free mail list:

Thanks for watching, I hope it helps!

Factor of Safety - Theories of Elastic Failure - Strength of Materials

Mechanics of Materials: Lesson 6 - Factor of Safety Explained, Example Problem

Factor of Safety

Factor of safety explained in simple terms

Factor of Safety and its importance | Factors of FOS | (Explain in detail)

Factor of Safety

Factor of Safety with Examples

How to choose Factor Of Safety: FOS | Stress strain curve simplified

Trending Tech - Protect Your Digital Identity: Essential Tips for Online Safety

Factor of Safety in hindi || Factor of safety SOM || Factor of safety strength of material || FoS

Stress CONCENTRATION Factors and Factor of Safety in 11 Minutes!

Factor of safety in design of structure | Why factor of safety is important in structural analyses?

What is factor of safety | why factor of safety (FOS) is important for product

Definition of Factor of Safety with Explanation - Introduction to Design of Machine - DOM

Axial Stress, Deflection and Factor of Safety Example - Part 1

What is Factor of Safety || Example Solved

FE Exam Practice - Factor of Safety - Mechanics of Materials

How To Calculate Safety Factor | Factor Of Safety Calculation | Factor Of Safety In Hindi

Find Factor of Safety and Displacement of I Beam in SolidWorks Simulation

Factor of Safety F.O.S

Factor of safety || SOM || Mechanical engineering

Factor of Safety|Margin of Safety|Stress-Strain| Mechanical -Civil Engineering

Engineering Secrets REVEALED: Learn Factor of Safety in Hindi!

WHAT IS FACTOR OF SAFETY | FOS | WITH EXAMPLES| ENGINEERING TIPS

Комментарии

0:05:54

0:05:54

0:18:16

0:18:16

0:05:46

0:05:46

0:02:36

0:02:36

0:12:16

0:12:16

0:07:36

0:07:36

0:07:55

0:07:55

0:25:29

0:25:29

0:07:02

0:07:02

0:07:50

0:07:50

0:11:26

0:11:26

0:03:38

0:03:38

0:02:54

0:02:54

0:18:43

0:18:43

0:07:43

0:07:43

0:06:40

0:06:40

0:10:16

0:10:16

0:04:27

0:04:27

0:12:09

0:12:09

0:06:43

0:06:43

0:01:09

0:01:09

0:00:44

0:00:44

0:02:58

0:02:58

0:02:58

0:02:58