filmov

tv

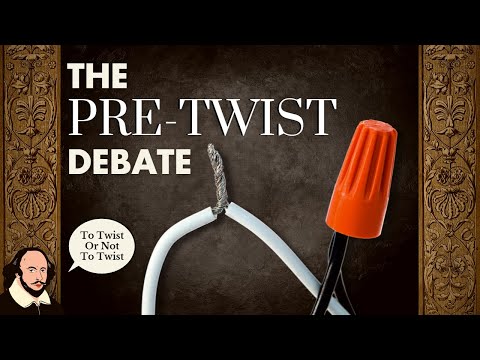

To Twist or not To Twist? THAT is the Question.

Показать описание

Pre-twisting your joints under a wire nut has been and continues to be an ongoing debate amongst most electricians for years. Some tradesmen do and some don’t. So, which is the correct way to do it? In today’s episode of Electrician U, Dustin sheds some light on the subject.

🤘⚡️EU Learning System⚡️🤘

-Video courses on every side of the electrical trade (theory, code, safety, wiring, install, troubleshooting, leadership, and more)

-Practice exams for 2017, 2020, 2023 code

-YouTube videos categorized and searchable

-Audio lessons

-Forum

-Business version has admin portal and ability to assign learning to technicians and monitor progress

-Any business size from 2 techs to 2,000!

🎓💡CONTINUING EDUCATION💡🎓

-State Approved

-Video Based

✍📝PRACTICE EXAMS📝✍

-2017, 2020, and 2023 NEC versions

-Online Residential Wireman Exam

-Online Journeyman Exam

-Online Master Exam

-300 Question Online Code Cannon (not license specific, all code)

-Take as many times as you want

-All of the above come with printable PDFs

🎤🎧PODCAST🎧🎤

Spotify:

Apple Podcast:

📱👍SOCIALS👍📱

🎧🎹Music, Editing, and Videography by Drake Descant and Rob LeBlanc🎹🎧

#electrician #electrical #electricity

The topic of pre-twisting your wires prior to putting a wire connector on has been one of the most widely debated practices in the electrical industry. And it continues to be one to this day! On one half of the divide are the tradesmen/electrical contractors that say that pre-twisting your wires will make a solid connection even when the wire connector is removed. On the other half of the fence are the tradesmen/electrical contractors that say pre-twisting your wires is a complete waste of time. With 2 clear lines drawn in the sand, how do we know which is actually the proper way to make up our wires?

To start the debate, let’s talk about the wire connectors themselves. Wire connectors of past years were not made the same as they are today. I think we have all been there- out on a service call trying to troubleshoot something only to find that there was an old wirenut that had loose conductors within it that dropped power to some device. Expansion and contraction of the wire from being energized/deenergized, stuff being plugged in and out could have the wires worked loose if you didn’t twist them together really well. But todays wirenuts will actually twist the wires much better than the old ones did. You can strip your wires, put the wirenut on, and when you remove it, your wires will be reasonably twisted together. Today also, we use a lot of pressure type wire connectors (push in type) that actually do not spin the wires at all.

On the other hand, as we have all been there too, trying to add or rework something where someone had twisted the wires together can be a time-consuming process. Having to untwist the wire bundle to add or remove a conductor and then having to straighten all the stripped wire out can be a royal pain! And again, many wire connections today rely on pressure type connectors and not a twist-on type wire connector and require no twisting at all, which results in a much faster installation.

In the end, it comes down to personal (or corporate) preference. Many of us become very proficient at the art of twisting the wires and the amount of time added is negligible when compared to the solid connection we get. Follow the manufacturer’s instructions for the specific type of wire connector you are using also. If the instructions tell you to pre-twist the wires, then pre-twist them. If it does not specifically tell you, then do what you, as a professional tradesman, feel gives you the most solid connection. The end result should be a joint that won't unintentionally come apart and will stay a solid connection.

We hope this has been an insightful look into the argument of whether to pre-twist your wires or not to pre-twist your wires. Is there a topic you would like to see discussed on Electrician U? Leave us a comment in the comments section and let us know. Please continue to follow Dustin and Electrician U as we are constantly updating our content to assist our followers in becoming the best electricians that they can be.

🤘⚡️EU Learning System⚡️🤘

-Video courses on every side of the electrical trade (theory, code, safety, wiring, install, troubleshooting, leadership, and more)

-Practice exams for 2017, 2020, 2023 code

-YouTube videos categorized and searchable

-Audio lessons

-Forum

-Business version has admin portal and ability to assign learning to technicians and monitor progress

-Any business size from 2 techs to 2,000!

🎓💡CONTINUING EDUCATION💡🎓

-State Approved

-Video Based

✍📝PRACTICE EXAMS📝✍

-2017, 2020, and 2023 NEC versions

-Online Residential Wireman Exam

-Online Journeyman Exam

-Online Master Exam

-300 Question Online Code Cannon (not license specific, all code)

-Take as many times as you want

-All of the above come with printable PDFs

🎤🎧PODCAST🎧🎤

Spotify:

Apple Podcast:

📱👍SOCIALS👍📱

🎧🎹Music, Editing, and Videography by Drake Descant and Rob LeBlanc🎹🎧

#electrician #electrical #electricity

The topic of pre-twisting your wires prior to putting a wire connector on has been one of the most widely debated practices in the electrical industry. And it continues to be one to this day! On one half of the divide are the tradesmen/electrical contractors that say that pre-twisting your wires will make a solid connection even when the wire connector is removed. On the other half of the fence are the tradesmen/electrical contractors that say pre-twisting your wires is a complete waste of time. With 2 clear lines drawn in the sand, how do we know which is actually the proper way to make up our wires?

To start the debate, let’s talk about the wire connectors themselves. Wire connectors of past years were not made the same as they are today. I think we have all been there- out on a service call trying to troubleshoot something only to find that there was an old wirenut that had loose conductors within it that dropped power to some device. Expansion and contraction of the wire from being energized/deenergized, stuff being plugged in and out could have the wires worked loose if you didn’t twist them together really well. But todays wirenuts will actually twist the wires much better than the old ones did. You can strip your wires, put the wirenut on, and when you remove it, your wires will be reasonably twisted together. Today also, we use a lot of pressure type wire connectors (push in type) that actually do not spin the wires at all.

On the other hand, as we have all been there too, trying to add or rework something where someone had twisted the wires together can be a time-consuming process. Having to untwist the wire bundle to add or remove a conductor and then having to straighten all the stripped wire out can be a royal pain! And again, many wire connections today rely on pressure type connectors and not a twist-on type wire connector and require no twisting at all, which results in a much faster installation.

In the end, it comes down to personal (or corporate) preference. Many of us become very proficient at the art of twisting the wires and the amount of time added is negligible when compared to the solid connection we get. Follow the manufacturer’s instructions for the specific type of wire connector you are using also. If the instructions tell you to pre-twist the wires, then pre-twist them. If it does not specifically tell you, then do what you, as a professional tradesman, feel gives you the most solid connection. The end result should be a joint that won't unintentionally come apart and will stay a solid connection.

We hope this has been an insightful look into the argument of whether to pre-twist your wires or not to pre-twist your wires. Is there a topic you would like to see discussed on Electrician U? Leave us a comment in the comments section and let us know. Please continue to follow Dustin and Electrician U as we are constantly updating our content to assist our followers in becoming the best electricians that they can be.

Комментарии

0:09:57

0:09:57

0:06:51

0:06:51

0:18:22

0:18:22

0:18:43

0:18:43

0:07:03

0:07:03

0:39:04

0:39:04

0:07:14

0:07:14

0:16:22

0:16:22

0:02:11

0:02:11

0:00:42

0:00:42

0:01:56

0:01:56

0:03:26

0:03:26

0:10:13

0:10:13

0:01:07

0:01:07

0:13:52

0:13:52

0:00:53

0:00:53

0:00:54

0:00:54

0:00:15

0:00:15

0:00:10

0:00:10

![[⁉️] LAY ALL](https://i.ytimg.com/vi/ThvLLuHPbEM/hqdefault.jpg) 0:00:29

0:00:29

0:00:19

0:00:19

0:16:47

0:16:47

0:00:59

0:00:59

0:01:01

0:01:01