filmov

tv

BUILDING A CUSTOM CAR CHASSIS IN 30 SECONDS!SUPER EASY WAY TO DO KUSTOM FRAME WORK! HOT RAT ROD

Показать описание

3 rolling chassis at MetalWorks Classic Auto & Speed Shop including Art Morrison & Roadster ...

SEMA Chassis Build w/ GSI Machine & Fabrication

Custom Roadster Shop Chassis: How it works...

RC car chassis 3D printed off road - DIY

The Ultimate Ford + Chevy Chassis [FULLY LOADED]

1928-1931 Ford Model A Chassis

BUILDING A CUSTOM CAR CHASSIS IN 30 SECONDS!SUPER EASY WAY TO DO KUSTOM FRAME WORK! HOT RAT ROD

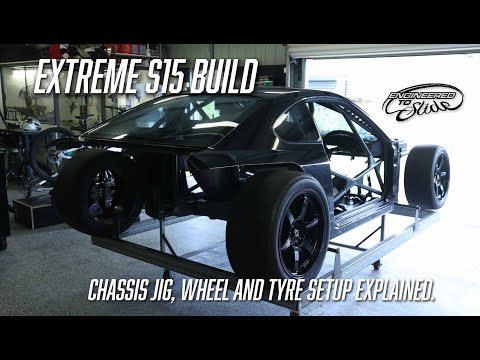

Extreme S15 Build : Chassis JIG, Tyre and Wheel setup explained.

💥 1970 Plymouth Road Runner Full Frame-Off Restoration |Build w/ Ceramic Coating!

FULLY Custom Mini Truck Chassis BUILD BREAKDOWN

We Might Delete this Video (our chassis engineering secrets)

We convinced Tim to make a Fox Body chassis so you can build one too.

SPEC 1964-70 Mustang chassis

Mini LEGO RC Car Chassis

All About frame JIG's and why your Restoration Project needs one!!!

TUBE CHASSIS BMW 630 PART 1 - ALUMINUM DASH BUILD

New Build! '62 Impala SS on a Custom Chassis & 24s

Useful Tips for DIY Chassis Table #dragbuild #automobile

The NEW 1953-1956 Custom Ford Truck Chassis | Fat Fender Garage

EARLY FORD HOT ROD CHASSIS AND SUSPENSION - A BEGINNER'S GUIDE

MY CRAZIEST HOT ROD TRUCK BUILD IS BACK! CUSTOM BUILT FRAME, CHOPPED, AIRBAGS! NO BUDGET KUSTOM RAT

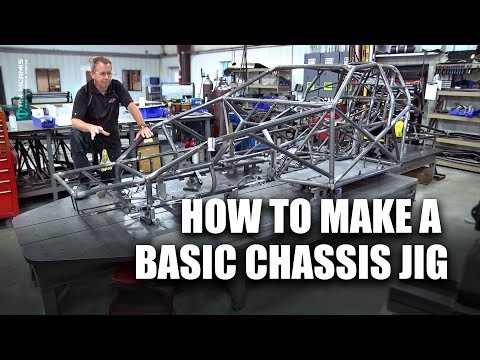

How To Make A Basic Chassis Jig

Chevy S10 Custom Rear Frame Rails

MEANER than a Lamborghini!?

Комментарии

0:01:59

0:01:59

0:07:38

0:07:38

0:03:16

0:03:16

0:00:16

0:00:16

0:08:57

0:08:57

0:04:44

0:04:44

0:00:35

0:00:35

0:08:54

0:08:54

0:00:55

0:00:55

0:13:11

0:13:11

0:23:50

0:23:50

0:03:54

0:03:54

0:00:55

0:00:55

0:00:15

0:00:15

0:29:23

0:29:23

0:03:58

0:03:58

0:06:30

0:06:30

0:00:22

0:00:22

0:05:01

0:05:01

0:07:25

0:07:25

0:12:57

0:12:57

0:06:50

0:06:50

0:05:23

0:05:23

0:00:12

0:00:12