filmov

tv

Modernizing The 1929 Ford Model A Valvetrain

Показать описание

Thank you to Antique Engine Rebuilding for the modern parts! Be sure to check them out for your Model A and B parts!

Instagram: @jamsionline

Facebook: JAMSI Online

TikTok: @jamsionline

Modernizing The 1929 Ford Model A Valvetrain

The Model E - 1930 Ford Model A Roadster All Electric EV Bolt In Conversion. Tesla battery & Hyp...

Ford Model A 4-cylinder engine rebuild time-lapse | Redline Rebuilds - S3E4

The Nuanced Design Of A 1929 Ford Model A Engine

1929 Ford Model A Roadster- How come nobody wants it?

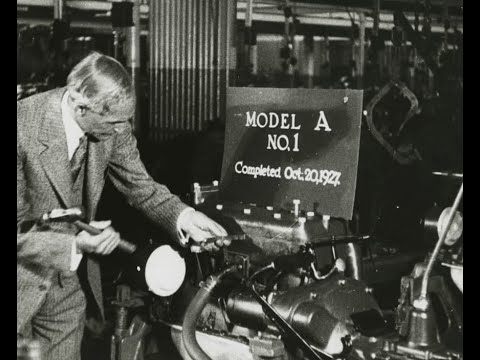

Building the Model A Ford Body on the Assembly Line 1928 1931

How The Model A Ford Engine Was Built; The Engine Assembly Line 1928 1931

A Model A that Runs on Wood?!?! Gasification modification to a 1929 Ford Tudor

Why did Ford Scrap all These Cars? 1929 Dis-Assembly Line Cash For Clunkers

Will These Modifications help this 1929 Model A go over 40 MPH?

1929 ford model A running

Upgrading a Model A distributor

'Zero RPM' Alternator for Ford Model A Cars is HERE!

Early Ford Wheels · ID Those Hot Rod Wheels you want!!!

Ford T vs New Car 🤯 3D Animation// What changed in engines in 100 years?

Ford Model A Burtz Block Unboxing, Build, First Start, and 1500 Mile Review

1928-1931 Ford Model A Chassis

Ford Model A Buyer's Guide - How to buy a 1928-1931 Ford Model A

Time to assemble the engine for our Model A Ford | Redline Update #20

Harbor Freight Predator swapped Ford Model A

Model A Ford Hydraulic Brake Conversion!

Making a 1930 Model A better than new!

Can You Believe He Drives This 1929 Model A Pickup In The Winter in the UP of Michigan?

Model A Ford Engine Numbers; What do they tell us?

Комментарии

0:18:16

0:18:16

0:14:58

0:14:58

0:07:56

0:07:56

0:16:14

0:16:14

0:09:30

0:09:30

0:06:22

0:06:22

0:10:11

0:10:11

0:04:33

0:04:33

0:04:44

0:04:44

0:34:28

0:34:28

0:00:17

0:00:17

0:08:46

0:08:46

0:09:20

0:09:20

0:22:13

0:22:13

0:08:14

0:08:14

0:37:14

0:37:14

0:04:44

0:04:44

0:18:55

0:18:55

0:14:48

0:14:48

0:02:50

0:02:50

0:11:28

0:11:28

0:01:00

0:01:00

0:16:11

0:16:11

0:06:51

0:06:51