filmov

tv

Copper Soft Jaws for a Bench VICE

Показать описание

Quick and easy DIY copper soft jaw inserts for any bench vice.

Tools I used(links support the channel)

I used plumbing 1/2inch type L copper which is thicker than type M. It is around 1/16" thick. A 1/16" cutoff disc was used to slice the copper.

#DIY #MAKE

Tools I used(links support the channel)

I used plumbing 1/2inch type L copper which is thicker than type M. It is around 1/16" thick. A 1/16" cutoff disc was used to slice the copper.

#DIY #MAKE

Making Copper Soft Jaws for the Four Jaw Chuck

Copper Soft Jaws for a Bench VICE

Making Copper Soft Jaws from Scrap Copper Pipe for the CJ0618 Lathe - TipBlitz19

Making copper soft jaws for Wilton vises

My take on copper soft jaws for lathe chucks

First Attempt Machining Copper - Making Copper Soft Jaws - C110

Making Soft Jaws for Vise Grips (HD)

Emmert 6A Toolmakers Vise Restoration - Part 3: Making Copper Soft Jaws

Copper Soft Jaws for the Mini Lathe - Rob's Garage

Restoring a Wilton bench vise and making copper soft jaws - Vise Restoration

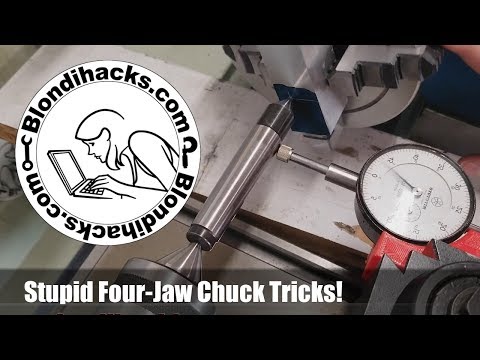

Stupid Four-Jaw Chuck Tricks

DIY Copper Soft Jaws For Bench Vise

Let's Make Soft Jaws

How to make perfect matching copper soft jaws

Making removable soft jaws for a 4-jaw lathe chuck

MAKING A SET OF SOFT JAWS FOR THE BENCH VISE

Lathe Soft Jaws in 5 Minutes - You Need These

Soft Lead Hard Grip? | Testing Lead Vise Jaws

MAKING COPPER VICE JAWS!

Copper soft jaws for the vice

How to Properly Cut Lathe Soft Jaws — Part 1: Fundamentals and OD Gripping

How to make copper vise jaws!

Copper Jaws for the Wilton Vise

Making copper soft jaws for FPU / Bison-Bial vise

Комментарии

0:07:45

0:07:45

0:07:33

0:07:33

0:04:48

0:04:48

0:30:20

0:30:20

0:11:05

0:11:05

0:35:43

0:35:43

0:03:12

0:03:12

0:17:23

0:17:23

0:06:14

0:06:14

0:10:13

0:10:13

0:11:27

0:11:27

0:25:14

0:25:14

0:22:14

0:22:14

0:04:23

0:04:23

0:04:46

0:04:46

0:05:00

0:05:00

0:07:16

0:07:16

0:04:59

0:04:59

0:07:28

0:07:28

0:00:14

0:00:14

0:13:29

0:13:29

0:08:16

0:08:16

0:05:20

0:05:20

0:08:15

0:08:15