filmov

tv

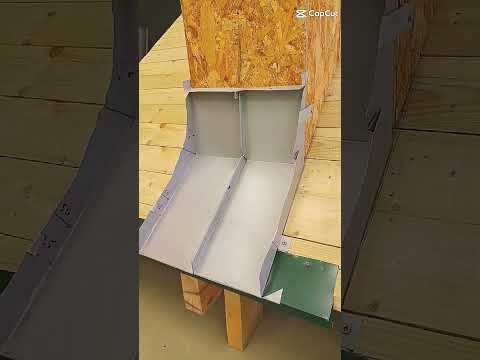

Chimney flashing on a metal roof.

Показать описание

Have you ever scratched your head trying to figure out how to flash a masonry chimney on a metal roof? In this video we demonstrate how it can be done, this is how we like to do masonry chimneys and it works great for us, you probably will need to find a metal roofing supplier who can make custom trims, if you do not have one already, so you can order your trim with at least a 5/8’ bend for brick and block chimneys, and 3’ for stone chimneys. Enjoy!

Here are some of the tools we like to use, these can be found on amazon via the following links;

You can also get this in a 24” length for Hemming the bottoms of valley angles on standing seam.

(AKA) Hiking Boots)

I am an Amazon associate, and may earn a commission if you purchase any of the products using the links I have listed in the description.

Here are some of the tools we like to use, these can be found on amazon via the following links;

You can also get this in a 24” length for Hemming the bottoms of valley angles on standing seam.

(AKA) Hiking Boots)

I am an Amazon associate, and may earn a commission if you purchase any of the products using the links I have listed in the description.

How to install chimney flashing when using Union's MasterRib metal roofing panel.

Metal Roofing Chimney Flashing Kit DIY Video - Mid Maine Metal

How to Install Standing Seam Metal Roofing - Flashing a Chimney

Chimney flashing on a metal roof.

Metal Roof Chimney Flashing 1 Front

How To Do Chimney Flashing

Dura Plus Chimney Pipe - Storm Collar

Metal roof Chimney flashing

chimney pipe flashing layout #standingseam #metalroof #sheetmetal #asm101

Installing Pipe Flashings on Metal Roofs

chimney flashing pocket fold #standingseam #metalroof #sheetmetal #alexprothmann

How Chimney Flashing SHOULD Look #shorts

Installing chimney flashing on a metal roof #construction

METAL ROOFING CHIMNEY FLASHING

Chimney Flashing Installation on a Standing Seam Metal Roof

Chimney & Flashing leak replacement & repairs. Caulk is temporary when you need a permanent...

How to: Flashing a chimney on a standing seam metal roof!!

Obadiah's: Redwood Hot Tub Installation - Installing Metal Roof Flashing

standing seam metal roofing euro style chimney flashing layout #standingseam #sheetmetal #asm101

How to Make a Chimney Pipe Roof Flashing with Sheet Metal

🔥METAL ROOFING CHIMNEY FLASHING

🔥STANDING SEAM METAL ROOFING CHIMNEY FLASHING

Metal Roof Chimney Flashing 4 Top Left and Gasket

🎥STANDING SEAM METAL ROOFING CHIMNEY FLASHING

Комментарии

0:04:17

0:04:17

0:09:11

0:09:11

0:03:31

0:03:31

0:07:51

0:07:51

0:06:56

0:06:56

0:06:08

0:06:08

0:01:59

0:01:59

0:00:16

0:00:16

0:00:15

0:00:15

0:21:16

0:21:16

0:00:21

0:00:21

0:00:21

0:00:21

0:00:27

0:00:27

0:00:12

0:00:12

0:11:54

0:11:54

0:00:32

0:00:32

0:15:28

0:15:28

0:03:20

0:03:20

0:00:23

0:00:23

0:17:50

0:17:50

0:00:16

0:00:16

0:00:16

0:00:16

0:07:27

0:07:27

0:00:13

0:00:13