filmov

tv

AIRFLOW TESTING: 8 Ways to Test Residential HVAC Airflows with Corbett Lunsford

Показать описание

Corbett Lunsford demonstrates 8 methods for airflow testing, including:

1. Exhaust Flow Pan (Energy Conservatory's Flow Meter)

2. Cardboard Box Flow Pan (handmade by Corbett)

3. Pressure Matching (FlowFinder from Retrotec)

4. Pressure Matching (Duc Tester from Retrotec)

5. Velocity Pressure (24" Pitot Tube from Dwyer)

6. Small Vane Anemometer (Testo 416)

7. Large Vane Anemometer (Testo 417)

8. Plastic Bag (30 gallon lightweight garbage bag)

For more on these diagnostics:

AIRFLOW TESTING: 8 Ways to Test Residential HVAC Airflows with Corbett Lunsford

PC Case AIRFLOW; A Visual Guide for Optimal Cooling.

Anemometer + Flow Hood: Discovering a Grille's K-Factor for HVAC Airflow Testing

Does your PC have good airflow?

Testing Airflow to Bullet Proof Your Code

How to optimize your case airflow!

Testing Airflow workflows - ensuring your DAGs work before going into production

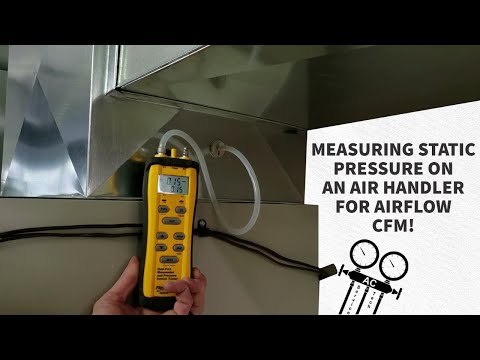

Measuring Static Pressure on an Air Handler for Airflow CFM!

Airflow Testing 8 (witch 2000's fan is the best?)

Phanteks NV5 PC Case Airflow test!

Airflow CFM Measured with a Hot Wire Anemometer!

HVAC Training: ERV Setup Testing/Commissioning, Using Pressure Curves to Measure Airflow (Renewaire)

Service Testing with Apache Airflow | Zhangyuan Hu @ PyBay 2018

Airflow 100: A Review of Air Velocity Testing Methods

Airflow smoke visualisation test - ProCleanroom

Service Done Right #13: Mass Airflow Sensor Testing – Is The Sensor Lying To The ECM?

Bionaire Window Fan with Twin 8.5-Inch Reversible Airflow Blades and Remote

Installation of the TDP05K Advanced Thermal Dispersion Airflow and Temperature Measuring Probe

Fan Airflow Test - Part I

Need your RV to cool down quicker? The RV Airflow system upgrade has been so amazing!

Airflow Balance Demo - How I'm Balancing Airflow Among the Three Collector Bays

Hyte Y60 Airflow comparison

Airflow Test - Magnuss MAGAF105T

Large airflow exhaust fan testing

Комментарии

0:11:03

0:11:03

0:12:39

0:12:39

0:07:01

0:07:01

0:00:16

0:00:16

0:58:56

0:58:56

0:15:20

0:15:20

0:51:14

0:51:14

0:08:08

0:08:08

0:10:18

0:10:18

0:00:18

0:00:18

0:11:57

0:11:57

0:10:31

0:10:31

0:29:03

0:29:03

1:01:48

1:01:48

0:00:41

0:00:41

0:08:25

0:08:25

0:01:47

0:01:47

0:03:50

0:03:50

0:24:35

0:24:35

0:00:19

0:00:19

0:02:18

0:02:18

0:00:13

0:00:13

0:02:33

0:02:33

0:00:22

0:00:22