filmov

tv

DIY Welding Table Fixtures and Clamps.

Показать описание

If you're considering buying a welding table, you're going to need fixtures and clamps to make the best use of the table. I cover DIY methods of making various fixtures and clamps.

This Tool Helps You Drill Holes In Your Welding Table.

ULTIMATE DIY Welding Table

The NEW Harbor Freight Welding Fixture Table

Welding Table Fast locking Fixture Clamp

Siegmund 3’x4’ Welding Table & Clamping Kit

DIY Welding Table Fixtures and Clamps.

Best Welding Fixture Table for Under $1,000?

How Many Welding Fixtures Do You Really Need?

NEW Harbor Freight Welding Fixture Table!!

Does the Fireball Tool Fixture Table live up to the hype of saving time and increasing precision?

180° T-Bar Clamp - KO | WT (KO Welding® Tables Australia)

3 Welding Tables for Small Shops: Owner's Review

This Is The Best Welding Table Ever Made. Solid Cast Iron. 3000lbs

DIY WELDING FIXTURE TABLE made only using a grinder and a welder ?

HOW TO BUILD $30 DIY welding fixture table. !!!!

Making Welding Table Clamps and Fixture

DIY Welding Fabrication Table - Stronghand On a Budget

A More Affordable Welding Table, And My First Job With It.

Langmuir Arcflat Welding Table - Best welding table?

I bought a 2000lbs Precision 3D Welding Table - Unboxing, Setup, Testing and Features

Welding Table Clamps for Cheap!

DIY fixture welding table and accessories.

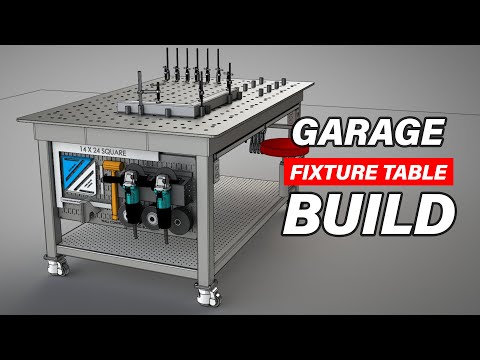

Homemade Welding Fixture Table + Storage Hack — Built for my Home Garage Shop

How to Weld Without a Welding Table. Fixture Like This To Make It Flat

Комментарии

0:07:42

0:07:42

0:08:38

0:08:38

0:18:06

0:18:06

0:00:22

0:00:22

0:09:04

0:09:04

0:20:28

0:20:28

0:05:32

0:05:32

0:06:01

0:06:01

0:03:21

0:03:21

0:00:39

0:00:39

0:08:30

0:08:30

0:21:33

0:21:33

0:28:27

0:28:27

0:11:46

0:11:46

0:11:34

0:11:34

0:15:06

0:15:06

0:22:13

0:22:13

0:06:46

0:06:46

0:22:00

0:22:00

0:05:33

0:05:33

0:03:02

0:03:02

0:16:51

0:16:51

0:06:13

0:06:13