filmov

tv

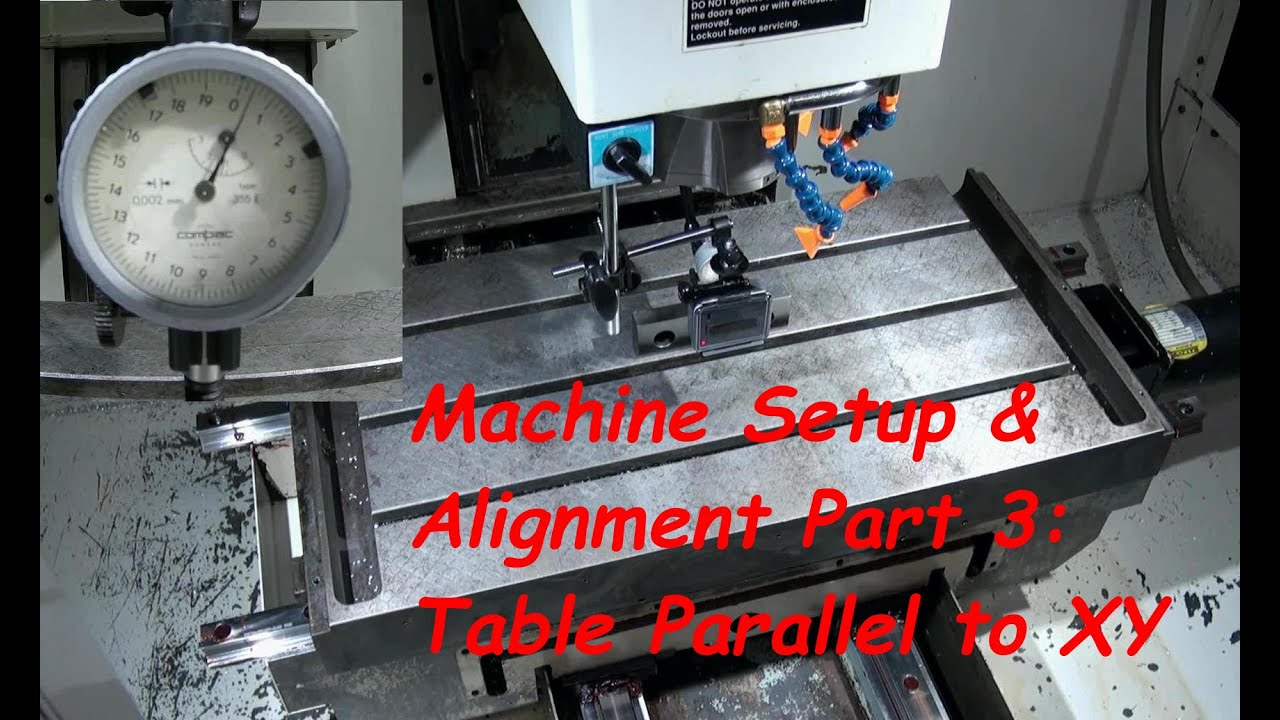

CNC Machine Setup and Alignment Part 3: Table Parallel to Motion

Показать описание

Hello everyone, welcome to At-Man Unlimited. This video series is on machine setup and alignment. We will walk through all the steps needed to get your machine making top notch accurate parts.

In this video we will check to see if the surface of the table moves parallel to the XY plane of motion. By using a dial indicator hanging from Z we can measure if our table is running parallel. We can also verify our table is flat.

If you would like to support the channel please visit our Patreon page

In this video we will check to see if the surface of the table moves parallel to the XY plane of motion. By using a dial indicator hanging from Z we can measure if our table is running parallel. We can also verify our table is flat.

If you would like to support the channel please visit our Patreon page

CNC Machine Setup and Alignment Part 1: Introduction

Punching tools setup for Trumpf Trumatic punch press machines

Lathe setup - Align or adjust tailstock using the Tailstock Alignment Bar by Edge Technology

CNC Router Alignment Steps for X, Y and Z Axis, Generic Alignment Steps for All Makes and Models

6090 CNC ROUTER DSP 0501 system setup, china cnc router, China cnc machine

Nine9 Center Height Adjusting Sleeve

CNC Machine Setup and Alignment Part 5: Squareness of XY

CNC Machine Setup and Alignment Part 2: Leveling

CNC Machine Setup and Alignment Part 8: Backlash

CNC Machine Setup and Alignment Part 9: Ball Screw Pitch Comp

CNC Machine Setup and Alignment Part 6: Z Alignment

Squaring and Tramming a DIY CNC Mill

CNC Machine Setup and Alignment Part 7: Spindle Tram

CNC Machine Setup and Alignment Part 4: Straightness of XY

CNC Fundamentals - Ep. 2 - How Machine Side the Bottom Side

Haas startup, setup, and running a job

CNC Machine Setup and Alignment Part 3: Table Parallel to Motion

Haas Apps Minute - Setting Two Vises Up for a Long Part

check x axis alignment & dial🤔 | cnc turning machine

Impressive CNC Lathe Machine Turning

5 Axis CNC Router Running Alignment Test. #cnc #cncrouter #5axismachining #alignment

Steady rest aligning - one of many ways to center your part in the steady rest - Quick tip -

Set Y-Axis on Sub Spindle | Swiss CNC Setup | Align Swiss Tools | Perfect Zero CNC Alignment

Destec On-Site Services - CNC Milling Using Laser Alignment

Комментарии

0:10:55

0:10:55

0:11:04

0:11:04

0:02:14

0:02:14

0:03:37

0:03:37

0:06:47

0:06:47

0:01:13

0:01:13

0:13:59

0:13:59

0:23:04

0:23:04

0:15:24

0:15:24

0:08:12

0:08:12

0:09:08

0:09:08

0:10:26

0:10:26

0:08:31

0:08:31

0:14:32

0:14:32

0:08:01

0:08:01

0:17:00

0:17:00

0:10:07

0:10:07

0:01:10

0:01:10

0:00:18

0:00:18

0:00:10

0:00:10

0:00:16

0:00:16

0:00:25

0:00:25

0:00:30

0:00:30

0:01:08

0:01:08