filmov

tv

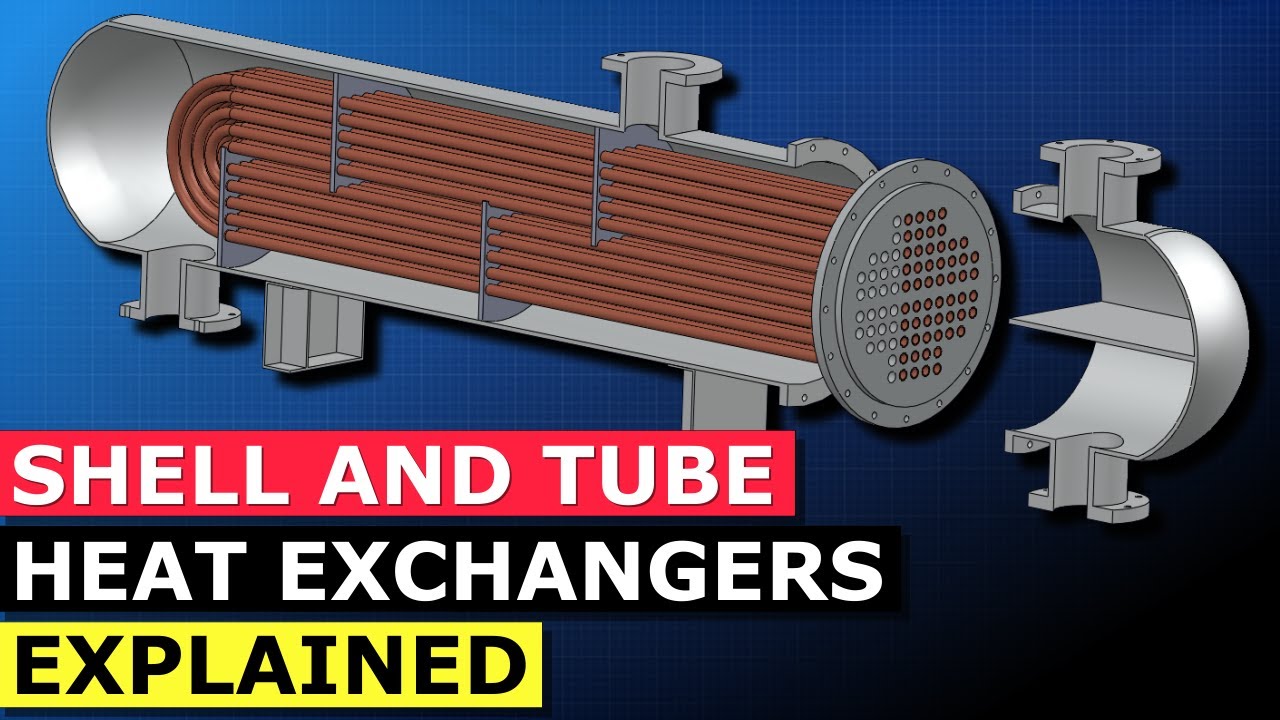

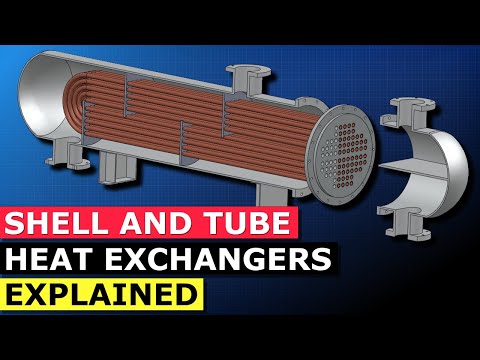

Shell and Tube Heat Exchanger basics explained

Показать описание

Shell and tube heat exchangers. Learn how they work in this video.

⚡🛠️ TOOLS YOU NEED 🛠️⚡

**************************************

MY FAVOURITE GEAR

👋 SOCIALISE WITH US 👋

*******************************

👀 Links - MUST WATCH!! 👀

*******************************

⚡ELECTRICAL ENGINEERING⚡

❄️ CHILLER ENGINEERING ❄️

🌡️ HVAC ENGINEERING 🌡️

⚗️ REFRIGERATION SYSTEMS 🌡️

⚗️ REFRIGERANTS ⚗️

🌊 HYDRONICS 🌊

🔥➡️❄️ HEAT EXCHANGERS 🔥➡️❄️

💻 DATA CENTERS 💻

🔬 PHYSICS 🔬

🎬 DOCUMENTARY 🎬

⚡🛠️ TOOLS YOU NEED 🛠️⚡

**************************************

MY FAVOURITE GEAR

👋 SOCIALISE WITH US 👋

*******************************

👀 Links - MUST WATCH!! 👀

*******************************

⚡ELECTRICAL ENGINEERING⚡

❄️ CHILLER ENGINEERING ❄️

🌡️ HVAC ENGINEERING 🌡️

⚗️ REFRIGERATION SYSTEMS 🌡️

⚗️ REFRIGERANTS ⚗️

🌊 HYDRONICS 🌊

🔥➡️❄️ HEAT EXCHANGERS 🔥➡️❄️

💻 DATA CENTERS 💻

🔬 PHYSICS 🔬

🎬 DOCUMENTARY 🎬

Shell and Tube Heat Exchanger basics explained

Campbell-Sevey - Shell and Tube Heat Exchanger

Shell And Tube Heat Exchanger Animation

Shell and Tube Heat Exchangers Explained! (Engineering)

Shell and Tube Heat Exchangers

Plate and Shell Heat Exchangers: Efficient Heat Transfer Solutions

Shell and tube heat exchanger manufacturer

Heat Exchanger components animation

Bell & Gossett 119 sq ft shell and tube heat exchanger

Customizable Shell and Tube Heat Exchangers

Shell and tube heat exchanger for oil and gas|Factory sales

Pharmaceutical-Grade Shell & Tube Heat Exchanger from Enerquip Thermal Solutions

10M² SHELL & TUBE HEAT EXCHANGER STAINLESS STEEL 316L

Shell and Tube Heat Exchanger Tube

Enerquip Shell and Tube Heat Exchanger.

Straight Tube Shell & Tube Heat Exchanger from Enerquip Thermal Solutions

ASME Shell Tube Heat Exchanger

Copper Return U Shaped Harin Tube Bending Machine For Shell Tube Heat Exchanger

Shell and Tube Heat Exchanger | Durable & Efficient Solution for Industrial Applications

Shell And Tube Heat Exchangers,stainless steel inner coil

Straight Tube Shell & Tube Heat Exchanger with Expansion Joint from Enerquip Thermal Solutions

Commercial Shell And Tube Heat Exchanger

Shell and Tube Heat Exchangers, Reactors, Condensers, or Static Mixers -Bliss Flow Systems

High quality titanium heat exchanger shell and tube evaporator for seawater

Комментарии

0:04:26

0:04:26

0:04:00

0:04:00

0:01:22

0:01:22

0:15:05

0:15:05

0:00:27

0:00:27

0:00:38

0:00:38

0:00:17

0:00:17

0:00:26

0:00:26

0:00:31

0:00:31

0:00:12

0:00:12

0:00:34

0:00:34

0:00:19

0:00:19

0:00:51

0:00:51

0:00:16

0:00:16

0:00:26

0:00:26

0:00:19

0:00:19

0:00:22

0:00:22

0:00:13

0:00:13

0:00:31

0:00:31

0:00:19

0:00:19

0:00:19

0:00:19

0:00:14

0:00:14

0:00:35

0:00:35

0:00:36

0:00:36