filmov

tv

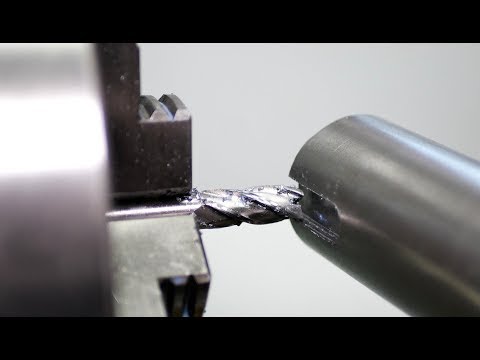

Cutting A Keyway On The Lathe

Показать описание

Cutting A Keyway On The Lathe

Three Ways To Cut Keyways! No special tools!

Cutting a Keyway on Manual Milling Machine

Cutting keyways in shafts

cutting a key way in a pulley #keyway #cutting #internal #slotting #inside #pulley #pulleys #machine

Keyway making how make Keyway without slater machine best idea Keyway cut on pully

Cutting a keyway on a shaft using a mill

keyway cutting in milling machine...

Keyway cutting on cnc wirecut edm machine

Cutting A Precision Internal Keyway With The Slotter #manualmachinist #machine

cutting a keyway

Transmission shaft keyway machining process - good tools and machinery make work more efficient

How to cut a keyway in a pulley with a broach.

MACHINE SHOP TIPS #151 Cutting a Keyway on the Lathe - a new ''abroach' tubalcain

DIY: Cut your own shaft Keyways

Cutting a Keyway WITHOUT a broach

How to cut a Keyway into a shaft

Hints & Tips # 001 Beginners Guide to Cutting a Keyway Using a Lathe 'mr factotum'

How to make KEYWAY on the LATHE

Dremel cutting a keyway slot in a motor shaft

Cutting A Keyway Into The 85RM2 Steering Wheel #crane #mechanic #diy #shaper #machine #repair #drott

cutting a keyway slot in a shaft

Keyways - Cutting Woodruff Key Slots and Broaching

keyway cutting

Комментарии

0:02:12

0:02:12

0:18:48

0:18:48

0:00:14

0:00:14

0:07:54

0:07:54

0:00:13

0:00:13

0:00:17

0:00:17

0:00:12

0:00:12

0:00:19

0:00:19

0:00:31

0:00:31

0:00:53

0:00:53

0:00:35

0:00:35

0:00:15

0:00:15

0:03:04

0:03:04

0:16:50

0:16:50

0:04:17

0:04:17

0:09:44

0:09:44

0:06:29

0:06:29

0:08:51

0:08:51

0:05:49

0:05:49

0:07:43

0:07:43

0:00:14

0:00:14

0:00:14

0:00:14

0:24:47

0:24:47

0:00:16

0:00:16