filmov

tv

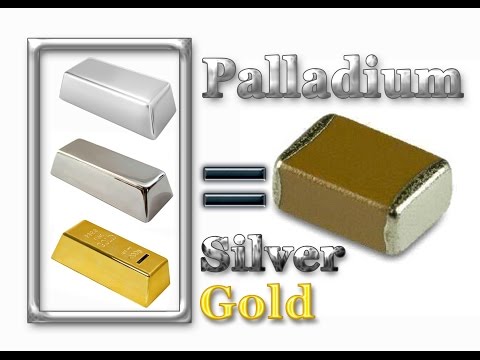

Palladium recovery from 1.4kg ceramic capacitors

Показать описание

Smelting 1.4kg MLCCs using lead and silver as collector metals, followed by cupellation and silver - palladium separation.

#palladium #palladiumrecovery #pallladiumrefining #owltech

#palladium #palladiumrecovery #pallladiumrefining #owltech

Palladium recovery from 1.4kg ceramic capacitors

Palladium Recovery from MLCC (Monolithic Ceramic Capacitors) | Palladium Recover | Palladium

How to recover silver, platinum and palladium from ceramic capacitor

palladium and platinum recovery from ceramic capacitors KM6 H90 1MO

250 kg CPU processors Gold Recovery #ewaste guess How much Gold?

💠Palladium, Silver and Gold recovery from MLCC (Monolithic Ceramic Capacitors)💠

Solution of base metals - Palladium recovery

Silver, And palladium, from ceramic, and polyester, Capacitor

multi-layer ceramic capacitors (MLCCs) yielding 50g+ palladium per Kg

Extracting gold from CPU computer scrap. Gold value in CPUs 1

Platinum-Palladium-Rhodium (PdRhodium) Fire Enrichment #foryou #refining

Tech Alchemy: Unveiling the Hidden Gems - Gold Ceramic Chip Extraction - White Ceramic High Yielding

Gold Recovery from 14kg CPUs

Gold Top IC Chips 2 Days In A Row

Ram IC chips for Gold Recovery #goldrecovery #ewasterecycling #goldram #scrapping #recycling

SuperbMelt 1-4kg Platinum melting furnace, Induction melting for platinum, gold, palladium, silver

Catalytic Converter Platinum/Palladium Recovery, Part 1

Ceramic CPUs: 5kg mix for GOLD recovery

Electronic Scrap Gold Recovery #shorts

Extracting gold and precious metals from old electronics, old fashion way😳

Sorting Components For Gold Recovery | Introducing The Components That contains Gold | Gold Recovery

melting PALLADIUM BLACK

Display PCB Boards Gold Recovery | Recover Gold From Display Boards

Gold recovery and refine from mixed rare vintage ceramic cpus and gold fingers full process

Комментарии

0:37:48

0:37:48

0:15:44

0:15:44

0:07:46

0:07:46

0:23:14

0:23:14

0:00:11

0:00:11

0:18:59

0:18:59

0:03:29

0:03:29

0:01:01

0:01:01

0:20:24

0:20:24

0:00:27

0:00:27

0:00:13

0:00:13

0:00:38

0:00:38

0:14:23

0:14:23

0:00:16

0:00:16

0:00:35

0:00:35

0:02:32

0:02:32

0:06:43

0:06:43

0:02:40

0:02:40

0:00:59

0:00:59

0:00:26

0:00:26

0:27:47

0:27:47

0:12:14

0:12:14

0:19:15

0:19:15

0:08:30

0:08:30