filmov

tv

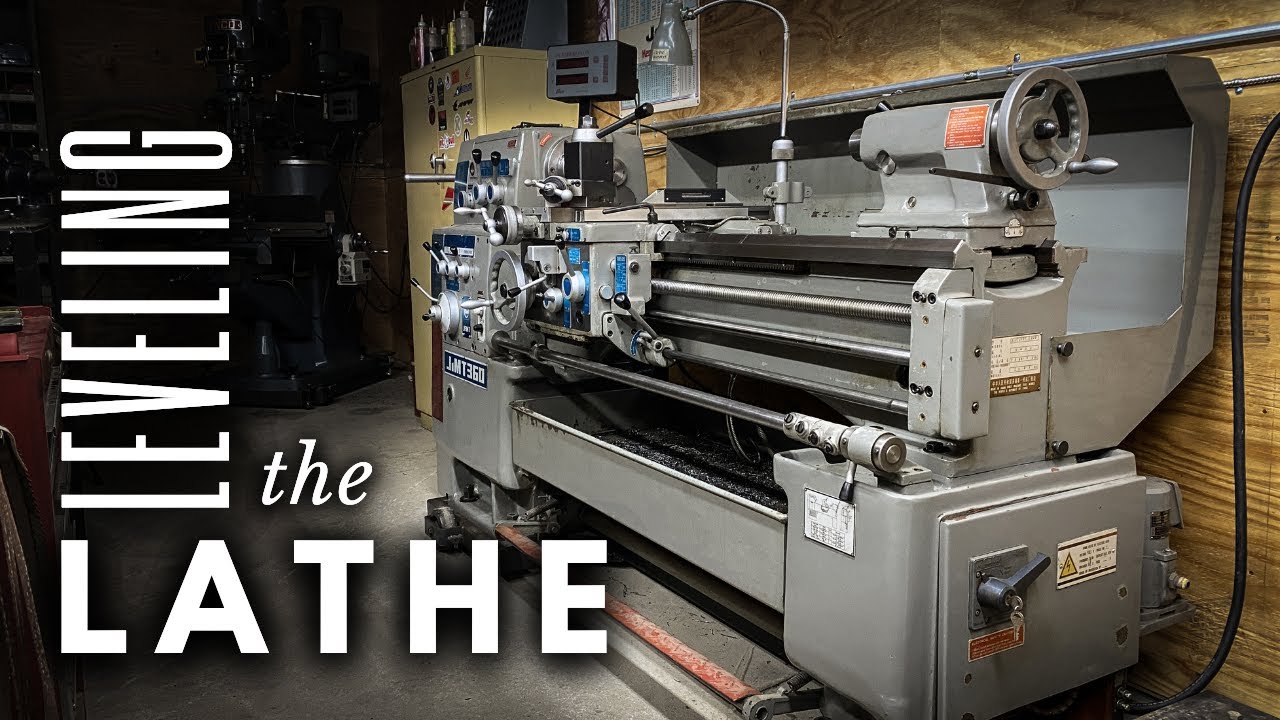

Lathe Leveling and Alignment || INHERITANCE MACHINING

Показать описание

Join me in the machine shop for a little engine lathe leveling and alignment 101, and quite possibly, just maybe, a few side projects. This is a long overdue project that evaded the lathe restoration, and for good reason. I had to make sure this is where I wanted this machine. The lathe leveling procedure is a fairly lengthy process and involves a precision level and an abundance of patience. Once the lathe is level with all twist and bow removed from the bed ways, we’ll move on to the headstock alignment. To do this, we’ll need some larger than average material, a dial indicator, and again, an abundance of patience. Once the headstock is parallel to the bed ways we can move on to the lathe tailstock alignment procedure. This is similar to the headstock alignment except we will be mounting the material between a dead center and live center, and driving the material with a lathe dog; in a process called turning between centers. And while we’re at it we’ll make a tailstock alignment bar. With the lathe alignment finally complete I can use it to make the custom precision mandrel for mounting the previously made collet blocks in the surface grinder. And try not to make them worse than they already are “cough-cough”.

#inheritancemachining #machineshop #artofthesideproject

TIMESTAMPS

0:00 Intro

1:16 Preparations

2:47 Leveling

5:55 Headstock Alignment

7:54 Tailstock Alignment

11:19 Making a Mandrel and Grinder Setup

13:00 Grinding and Inspecting

FAQ

Editing: Final Cut Pro X

Intro Song: Way Back Way Back When (Instrumental Version) - Gamma Skies

© 2022 Inheritance Machining, LLC. All Rights Reserved.

#inheritancemachining #machineshop #artofthesideproject

TIMESTAMPS

0:00 Intro

1:16 Preparations

2:47 Leveling

5:55 Headstock Alignment

7:54 Tailstock Alignment

11:19 Making a Mandrel and Grinder Setup

13:00 Grinding and Inspecting

FAQ

Editing: Final Cut Pro X

Intro Song: Way Back Way Back When (Instrumental Version) - Gamma Skies

© 2022 Inheritance Machining, LLC. All Rights Reserved.

Комментарии

0:14:52

0:14:52

0:16:55

0:16:55

0:18:13

0:18:13

0:05:38

0:05:38

0:22:15

0:22:15

0:06:24

0:06:24

0:12:01

0:12:01

0:07:02

0:07:02

0:01:30

0:01:30

0:40:09

0:40:09

0:05:24

0:05:24

0:07:15

0:07:15

1:16:34

1:16:34

0:28:34

0:28:34

0:42:25

0:42:25

0:03:13

0:03:13

0:30:07

0:30:07

0:29:29

0:29:29

0:10:44

0:10:44

0:34:46

0:34:46

0:32:05

0:32:05

0:30:29

0:30:29

0:29:18

0:29:18

0:14:59

0:14:59