filmov

tv

The BEST Metal Casting Alloy That Everyone Ignores

Показать описание

Want to support the channel?

Mailing Address:

1818 Milton Ave STE 100 # 1973

Janesville, WI 53545-9998

#metalcasting

The BEST Metal Casting Alloy That Everyone Ignores

Metal Casting Alloys Matter More Than You Think...

The BEST Metal Casting Alloy That Everyone Ignores |Metal casting at home|

The EASIEST Method for Metal Casting (open mold)

The BEST Metal Casting Alloy That Everyone Ignores |Metal casting at home|

9 Things I Didn't Know Before Building a foundry: Casting 101

The Bronze Alloy as Tough as Steel! (almost)

Casting Metal: showcasing the basics of casting and the Casting is the future Foundry Kit

3D Print to Solid Metal, BETTER Than Lost PLA Casting

You Need to Know This Before You Sand Cast

Homemade Gear Casting, method of homemade silicone

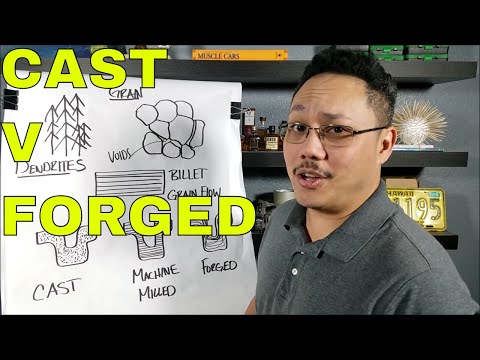

CAST VS FORGED PARTS WHY CAST IS BAD AND WHY FORGED IS BETTER

From Bad To AWESOME, 1 Year of Sand Casting. What I have learned in my 1st year of sand casting.

Making tools from sand diy |The BEST Metal Casting Alloy That Everyone Ignores|

Simple aluminum alloy casting machine (auto parts production)

Best Metal Casting Machine in 2023 | Top 7 - Best Melting Furnace - Review

High Performance Aluminum Casting Alloys for Engine Applications

Removing rust from very old railroad spikes

Al Metal Casting: Tips for Making Good & BIG ones at home!

TOP 5 Best Melting Furnace: Today’s Top Picks

Initial SETUP COST To Melt Metal At Home - FULL BREAKDOWN Of The Tools Needed

Top Alloy Steel and Metal Casting | Manufacturers and Suppliers

Metal Casting using a Copper Alloy (Melting Copper)

Watch metal melting on sand #shorts

Комментарии

0:09:24

0:09:24

0:09:21

0:09:21

0:00:31

0:00:31

0:08:59

0:08:59

0:02:59

0:02:59

0:15:36

0:15:36

0:06:36

0:06:36

0:15:20

0:15:20

0:11:27

0:11:27

0:09:13

0:09:13

0:08:07

0:08:07

0:04:16

0:04:16

0:11:15

0:11:15

0:03:03

0:03:03

0:00:20

0:00:20

0:07:55

0:07:55

0:45:44

0:45:44

0:01:01

0:01:01

0:19:26

0:19:26

0:10:16

0:10:16

0:13:20

0:13:20

0:01:15

0:01:15

0:04:39

0:04:39

0:00:17

0:00:17