filmov

tv

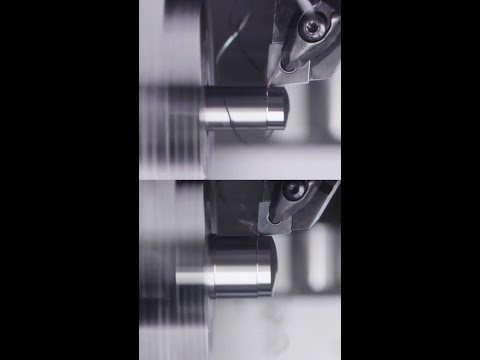

Hardbreaker Series - CBN inserts with integrated chipbreaker for improved hard turning productivity

Показать описание

Optimized chipbreaker geometry significantly reduces cutting force imposed on the cutting edge, ensuring long tool

Hardbreaker Series

Cutting condition

Machinig video ①

Insert:2QP-CNGM120408-HP BXA20

Vc = 150 m/min

f = 0.15 mm/rev

ap = 0.15 mm

Work material:SCM420/18CrMo4

Machinig video ②

Hardbreaker HP:2QP-CNGM120408-HP BXM10

Conventional :2QP-CNGA120408 BXM10

Vc = 150 m/min

f = 0.15 mm/rev

ap = 0.15 mm

Work material:SCM420/18CrMo4

Machinig video ③

Hardbreaker HP:2QP-CNGM120408-HP BXM10

Conventional :2QP-CNGA120408 BXM10

Vc = 180 m/min

f = 0.15 mm/rev

ap = 0.15 mm

Work material:SCM420/18CrMo4

#shorts

#cnc

#machine

#machining

#tools

#ev

Hardbreaker Series

Cutting condition

Machinig video ①

Insert:2QP-CNGM120408-HP BXA20

Vc = 150 m/min

f = 0.15 mm/rev

ap = 0.15 mm

Work material:SCM420/18CrMo4

Machinig video ②

Hardbreaker HP:2QP-CNGM120408-HP BXM10

Conventional :2QP-CNGA120408 BXM10

Vc = 150 m/min

f = 0.15 mm/rev

ap = 0.15 mm

Work material:SCM420/18CrMo4

Machinig video ③

Hardbreaker HP:2QP-CNGM120408-HP BXM10

Conventional :2QP-CNGA120408 BXM10

Vc = 180 m/min

f = 0.15 mm/rev

ap = 0.15 mm

Work material:SCM420/18CrMo4

#shorts

#cnc

#machine

#machining

#tools

#ev

Hardbreaker Series - CBN inserts with integrated chipbreaker for improved hard turning productivity

Hardbreaker Series - CBN inserts with integrated chipbreaker for improved hard turning productivity

CBN inserts for high speed machining of super hard steel (HRC63)

Four types of CBN inserts

TungCut CBN - Innovative CBN inserts for accelerated machining of hard part turning

Use CBN Super Hard Inserts Cut HRC63 Hardened Steel

PCD AND CBN INSERTS

PCD and solid CBN inserts

CBN inserts for high-speed machining of bearing steel (HRC67)

PCD/CBN Inserts for Machining Rolls——High-quality Diamond tools

BNC2105 Grade - Coated CBN Series for Hardened Steel

CBN insert vs. 60hrc hardened steel

High Speed Turning of PCBN/CBN Inserts

DNC- DINE Coated cBN series

Do CBN inserts (chipbreakers) really work that well? #cbn #cbntools #chipbreaker #machining #gears

CBN insert machining superhard bearing steel (HRC64)

CBN inserts for cutting / turning / milling

Do you know how to grind PCD Inserts

Funik Solid CBN Inserts

MORESUPERHARD--CBN insert processing

Solid CBN Inserts for Hard Turning Cast Iron and Hardened Steel

Solid CBN Inserts Manufacturer——WNGN Type

grinding wheel for indexable inserts (pcd, cbn)

Standard Insert vs Chip Breaker

Комментарии

0:00:24

0:00:24

0:00:13

0:00:13

0:00:24

0:00:24

0:01:41

0:01:41

0:01:28

0:01:28

0:01:06

0:01:06

0:01:25

0:01:25

0:00:30

0:00:30

0:00:25

0:00:25

0:00:14

0:00:14

0:01:12

0:01:12

0:00:37

0:00:37

0:00:19

0:00:19

0:01:52

0:01:52

0:00:08

0:00:08

0:00:21

0:00:21

0:00:16

0:00:16

0:00:19

0:00:19

0:00:11

0:00:11

0:00:15

0:00:15

0:00:26

0:00:26

0:00:15

0:00:15

0:00:07

0:00:07

0:00:08

0:00:08