filmov

tv

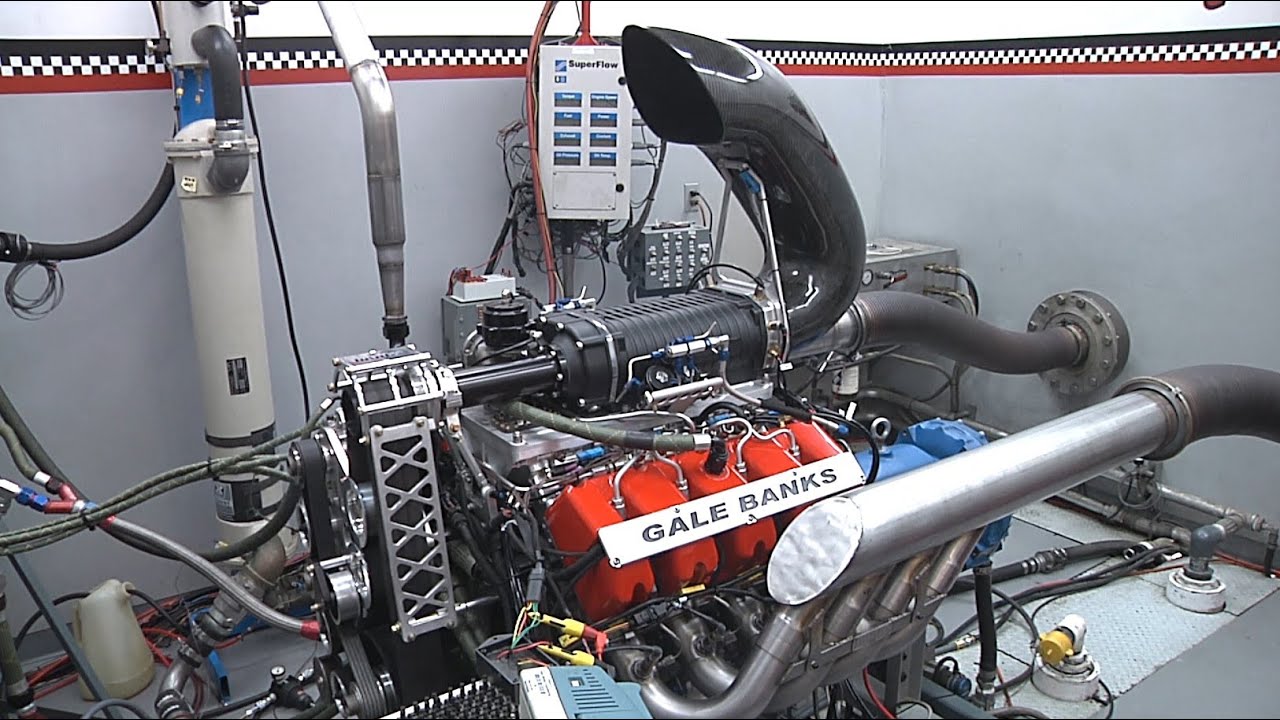

First Fire: Banks Supercharged Duramax 871S

Показать описание

First Fire: Banks Supercharged Duramax 871S

SUPER-TURBO DURAMAX FIRST FIRE! Building A Monster Truck Engine Pt 12

First Startup of our Supercharged Duramax Engine (most responsive engine we’ve ever heard!)

You've Never heard a Diesel Rev This Fast!

Supercharged Duramax getting Ready for SEMA

FIRST FIRE! | Building A Monster Truck Engine Pt 5

Banks water injection: Supercharged Duramax 871S

Top Fuel 6.6L Duramax Dragster

2024 Duramax L5P Engine First Look And Comparison | Banks Exclusive

Inside the most powerful Duramax yet.

Surprising DMAX plant staff with a supercharged Duramax

That time Gale Banks fired up a twin-turbo on Spike TV

Everything you need to know about our supercharged Duramax

Twin Turbo Supercharged Diesel Engine

How a Roots supercharger works

Lb7 duramax diesel vs supercharged civic si

Super charged, twin turbo charged High rpm 7.0 l duramax

Inside Banks SUPERCHARGED DURAMAX engine | BANKS BUILT Ep 40

SEMA Reacts to our Supercharged Duramax

SUPER-TURBO DURAMAX FIRST LOOK: Building A Monster Truck Engine Pt 10

You've never heard a Duramax this angry! 🤬😈

T-1000 First Fire.

The first supercharged Duramax camshaft! | BANKS BUILT Ep 16

Evil Duramax Spoolup Dirt toss #shorts

Комментарии

0:00:48

0:00:48

0:07:32

0:07:32

0:17:33

0:17:33

0:01:00

0:01:00

0:00:20

0:00:20

0:30:35

0:30:35

0:00:42

0:00:42

0:00:50

0:00:50

0:24:18

0:24:18

0:00:49

0:00:49

0:00:44

0:00:44

0:09:29

0:09:29

0:09:22

0:09:22

0:00:18

0:00:18

0:00:56

0:00:56

0:00:17

0:00:17

0:00:11

0:00:11

0:18:53

0:18:53

0:01:00

0:01:00

0:16:01

0:16:01

0:00:34

0:00:34

0:00:15

0:00:15

0:27:03

0:27:03

0:00:20

0:00:20