filmov

tv

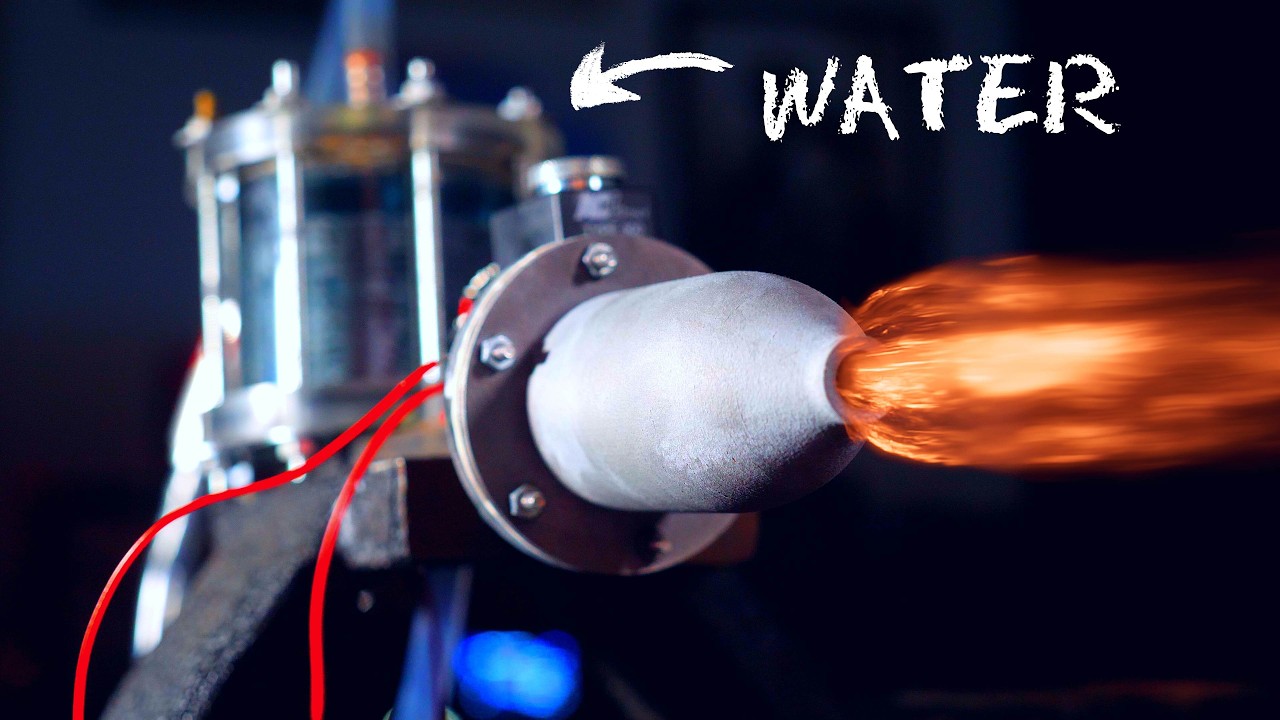

ROCKET that LITERALLY BURNS WATER as FUEL

Показать описание

3D Models

Materials

Machines

#engine #rocket #3dprinting

ROCKET that LITERALLY BURNS WATER as FUEL

Why rockets eject half a million gallons of water

SHE PULLED THE SWORD OUT OF THE STONE RIGHT IN FRONT OF ME IN DISNEY WORLD

The Best Performing (and most dangerous) Chemical Rocket Ever Tested: Rocketdyne Tripropellant

Why don't rocket engines melt? How engineers keep engines cool

How Much Do Rockets Pollute? Are They Bad For Our Air?

What's Going On In This SpaceX Rocket Video?

SpaceX's Water Landing Reveals Rocket 'Secrets' (or, What We Learned from CRS-16)

Defying Atmosphere - How Rocket Engines Get Tested In A Vacuum Before Going To Space

Green screening myself into Station 19's Rocket Water Heater crap show.

Rocket Scientists Answer Questions From Twitter | Tech Support | WIRED

Rocket Science: Explained (Also - NASA found water on the moon so let’s chat about it)

The rocket motor that broke me

Model Rocket Engine In A Vacuum Chamber - 4K Slow Motion - will it burn? - Rockets (S1 • E3)

Rocket Monday Ep67 (ARCA Steam Rocket Explained)

Ethanol/oxygen liquid fuel rocket engine test compilation

Turn Empty Water Bottles Into Alcohol Fueled Rockets

How Fire Burns in Space

Liberator ROCKET Heater -Pellets w/ NO ELECTRICITY !!!

Engineering Connections (Richard Hammond) - Space Shuttle | Science Documentary | Reel Truth Science

What keeps everyone safe when rockets fail? Why did the failed Falcon 9 rocket land in the ocean?

I Built The First LAMINAR FLOW ROCKET ENGINE

Rocket heater pulsing burn shakes the room / heating German V2 A4 rocket rudder part

What it's like inside rocket engines! Viking 2 and Vulcain 1!

Комментарии

0:19:00

0:19:00

0:04:33

0:04:33

0:00:41

0:00:41

0:53:44

0:53:44

0:26:31

0:26:31

0:55:46

0:55:46

0:12:40

0:12:40

0:14:16

0:14:16

0:11:21

0:11:21

0:03:16

0:03:16

0:14:32

0:14:32

0:08:25

0:08:25

0:25:11

0:25:11

0:05:30

0:05:30

0:09:51

0:09:51

0:00:42

0:00:42

0:02:12

0:02:12

0:03:02

0:03:02

0:17:57

0:17:57

0:50:00

0:50:00

0:28:10

0:28:10

0:15:51

0:15:51

0:02:36

0:02:36

0:26:01

0:26:01