filmov

tv

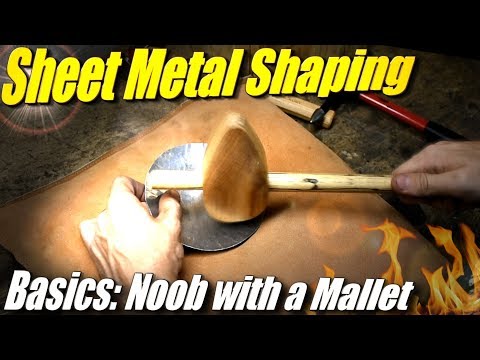

Making a Sheet Metal Forming Press Die - Test

Показать описание

Please direct all correspondence to:

Craig's Machine Shop

2753 E. Broadway Rd Ste. 101-PMB416

Mesa, Az 85204-1570

3D Printed Sheet Metal Forming (Part 2)

Machina - Incremental Metal Sheet Forming

Making a Sheet Metal Forming Press Die - Test

3D Printed Sheet Metal Forming Pt. 2 - Custom Dies

Deep drawing press machine, Hydraulic press for sheet metal, TSINFA

Reshaping History with Digital Sheet Forming

The Figur G15 | All-New Digital Sheet Forming Technology

How to make a complex patch panel | Metal Fabrication | Sheet Metal Shaping

#sheet metal dies #trimming #forming #diemakers #deepdraw #presstoolmakers 8558996426, 9816465420

Common 13 Types of Sheet Metal Fabrication Techniques

Shaping Sheet Metal with a Mikwaukee m12 palm nailer

DIY Hydroforming Tutorial

Sheet Metal Parts HOW IT'S MADE (B&B Manufacturing

pipe forming tool press tool sheet metal pressshop pipe

See How Sheet Metal Working Changes Everything!

Sheet Metal Parts in Minutes | Digital Sheet Metal Forming at Evology Mfg.

Sheet Metal Shaping: Noob with a Sandbag, Shrinking Stump, and Planishing Anvil

Metal forming tool | Lever machine | Tucking tool for sheet metal fabrication | DIY gathering tool

Sheet Metal Fabrication -MB Bead Roller, Covell Round Over Dies, & MB Dimple Dies - Trick-Tools....

3D printed sheet metal forming. Will it survive???

Forming Sheet Metal & Metal Forming Tools - Uses Explained By Gene Winfield at SEMA

Cutting, Bending, Assembling a Sheet Metal Plenum Box using a Brake and Hand Tools!

Ripple sheet metal forming - Technology machine & tool make work easy

Metal Shaping with ONLY Hand Tools STEP BY STEP!!! How To Make Compound Curves

Комментарии

0:15:03

0:15:03

0:00:52

0:00:52

0:08:17

0:08:17

0:23:56

0:23:56

0:00:52

0:00:52

0:06:59

0:06:59

0:03:59

0:03:59

0:08:53

0:08:53

0:00:11

0:00:11

0:03:55

0:03:55

0:08:23

0:08:23

0:07:38

0:07:38

0:04:50

0:04:50

0:00:21

0:00:21

0:00:23

0:00:23

0:02:43

0:02:43

0:19:04

0:19:04

0:11:26

0:11:26

0:01:26

0:01:26

0:16:56

0:16:56

0:46:45

0:46:45

0:00:59

0:00:59

0:00:05

0:00:05

0:56:07

0:56:07