filmov

tv

How ETR and DTR Components Enhance 4Hi Rolling Mills

Показать описание

We're thrilled to share the successful installation of ETR (Entry Tension Reel) and DTR (Delivery Tension Reel) components for a 4Hi rolling mill in Gujarat! The results? Absolutely flawless! Check out the remarkable finish on the coil – a testament to our commitment to delivering quality solutions that meet and exceed expectations.

At VSR Rolling Mills, our dedication to innovation and excellence goes beyond just providing machines; we offer comprehensive solutions tailored to meet your specific needs. This recent installation highlights the importance of precision and quality in every aspect of the rolling mill process.

1. Understanding ETR and DTR Components:

ETR (Entry Tension Reel): This component plays a crucial role in maintaining the tension of the metal strip as it enters the rolling mill. Proper tension ensures that the strip remains flat and free from defects, leading to a superior final product.

DTR (Delivery Tension Reel): The DTR maintains the tension of the metal strip as it exits the rolling mill. This is essential for preventing any slack or over-tension, which could compromise the quality and uniformity of the rolled product.

2. The Importance of Tension Control:

Quality Improvement: Maintaining the correct tension throughout the rolling process helps in achieving a consistent thickness and surface finish, minimizing any potential defects.

Process Efficiency: Proper tension control ensures smoother operation, reducing the risk of breakdowns and increasing overall production efficiency.

Product Integrity: Consistent tension prevents issues such as buckling or wrinkling of the metal strip, ensuring that the final product meets the highest quality standards.

3. Installation in Gujarat:

Site Preparation: Our team began with a thorough site assessment to ensure that the existing infrastructure could support the new components.

Component Installation: The ETR and DTR components were carefully installed, calibrated, and tested to ensure optimal performance.

Performance Testing: After installation, rigorous testing was conducted to ensure that the components operated seamlessly with the 4Hi rolling mill, delivering the desired results.

4. The Results:

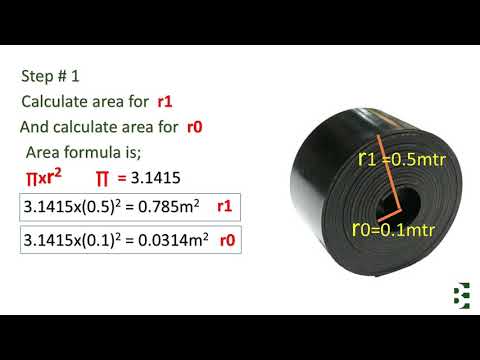

Flawless Finish: The installed components resulted in a flawless finish on the coil, demonstrating the precision and efficiency of our solutions.

Customer Satisfaction: The remarkable finish and enhanced performance were greatly appreciated by our client, highlighting our commitment to exceeding expectations.

5. VSR Rolling Mills Solutions:

Comprehensive Services: From spare parts to complete rolling mills and annual maintenance contracts, VSR Rolling Mills provides a wide range of solutions to meet diverse industrial needs.

Customized Support: Our team of experts is always ready to assist with any specific requirements or inquiries, ensuring that our clients receive tailored solutions.

Commitment to Quality: Quality is at the core of everything we do. We strive to deliver solutions that not only meet but exceed industry standards.

6. Future Outlook:

Continuous Innovation: We are constantly innovating to improve our products and services, ensuring that we stay ahead in the industry.

Client-Centric Approach: Our clients' success is our business. We are committed to building long-term relationships based on trust, quality, and exceptional service.

In conclusion, the successful installation of ETR and DTR components for the 4Hi rolling mill in Gujarat is a clear demonstration of VSR Rolling Mills' expertise and dedication to quality. We look forward to continuing to provide innovative solutions that drive success for our clients.

Tags:

#RollingMill #SuccessStory #QualityMatters #VSRRollingMills #4Hi #ETR #DTR #Copper #Metalworking #IndustrialSolutions #Manufacturing #Innovation #Engineering #CustomerSatisfaction #IndustrialAutomation #ProcessEfficiency

At VSR Rolling Mills, our dedication to innovation and excellence goes beyond just providing machines; we offer comprehensive solutions tailored to meet your specific needs. This recent installation highlights the importance of precision and quality in every aspect of the rolling mill process.

1. Understanding ETR and DTR Components:

ETR (Entry Tension Reel): This component plays a crucial role in maintaining the tension of the metal strip as it enters the rolling mill. Proper tension ensures that the strip remains flat and free from defects, leading to a superior final product.

DTR (Delivery Tension Reel): The DTR maintains the tension of the metal strip as it exits the rolling mill. This is essential for preventing any slack or over-tension, which could compromise the quality and uniformity of the rolled product.

2. The Importance of Tension Control:

Quality Improvement: Maintaining the correct tension throughout the rolling process helps in achieving a consistent thickness and surface finish, minimizing any potential defects.

Process Efficiency: Proper tension control ensures smoother operation, reducing the risk of breakdowns and increasing overall production efficiency.

Product Integrity: Consistent tension prevents issues such as buckling or wrinkling of the metal strip, ensuring that the final product meets the highest quality standards.

3. Installation in Gujarat:

Site Preparation: Our team began with a thorough site assessment to ensure that the existing infrastructure could support the new components.

Component Installation: The ETR and DTR components were carefully installed, calibrated, and tested to ensure optimal performance.

Performance Testing: After installation, rigorous testing was conducted to ensure that the components operated seamlessly with the 4Hi rolling mill, delivering the desired results.

4. The Results:

Flawless Finish: The installed components resulted in a flawless finish on the coil, demonstrating the precision and efficiency of our solutions.

Customer Satisfaction: The remarkable finish and enhanced performance were greatly appreciated by our client, highlighting our commitment to exceeding expectations.

5. VSR Rolling Mills Solutions:

Comprehensive Services: From spare parts to complete rolling mills and annual maintenance contracts, VSR Rolling Mills provides a wide range of solutions to meet diverse industrial needs.

Customized Support: Our team of experts is always ready to assist with any specific requirements or inquiries, ensuring that our clients receive tailored solutions.

Commitment to Quality: Quality is at the core of everything we do. We strive to deliver solutions that not only meet but exceed industry standards.

6. Future Outlook:

Continuous Innovation: We are constantly innovating to improve our products and services, ensuring that we stay ahead in the industry.

Client-Centric Approach: Our clients' success is our business. We are committed to building long-term relationships based on trust, quality, and exceptional service.

In conclusion, the successful installation of ETR and DTR components for the 4Hi rolling mill in Gujarat is a clear demonstration of VSR Rolling Mills' expertise and dedication to quality. We look forward to continuing to provide innovative solutions that drive success for our clients.

Tags:

#RollingMill #SuccessStory #QualityMatters #VSRRollingMills #4Hi #ETR #DTR #Copper #Metalworking #IndustrialSolutions #Manufacturing #Innovation #Engineering #CustomerSatisfaction #IndustrialAutomation #ProcessEfficiency

0:01:30

0:01:30

0:05:50

0:05:50

0:00:16

0:00:16

0:00:15

0:00:15

0:01:27

0:01:27

0:00:22

0:00:22

0:16:28

0:16:28

0:00:54

0:00:54

0:03:30

0:03:30

0:00:51

0:00:51

0:02:24

0:02:24

0:02:43

0:02:43

0:08:55

0:08:55

0:00:16

0:00:16

0:00:42

0:00:42

0:01:49

0:01:49

0:00:34

0:00:34

0:01:08

0:01:08

0:01:42

0:01:42

0:00:16

0:00:16

0:03:06

0:03:06

0:02:22

0:02:22

0:00:46

0:00:46

0:00:05

0:00:05