filmov

tv

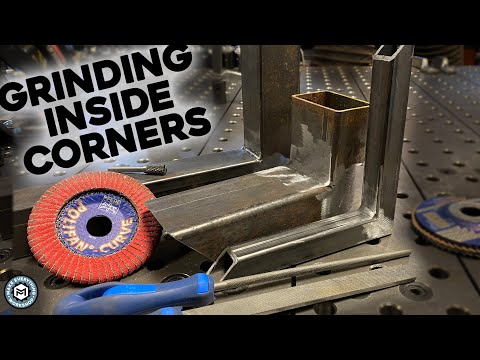

Weld Seam Removal: Grinding Disc vs. Fibre Disc vs. SMT Flap Disc | KLINGSPOR Abrasives USA

Показать описание

Weld removal is an application that gives you choices. Often it's just a matter of preference, however, there are advantages to all three, flap disc, fibre disc and grinding disc.

Grinding Discs are the most aggressive and remove lots and lots of material in a short period of time. However, they are usually very loud, vibrate a lot and leave plenty of spots and marks around the weld.

Fibre Discs are the intermediate product. They are not quite as aggressive, but still fast when removing weld seams and leave a nicer surface that needs less clean up.

Be aware though that the grinding area is somewhat wider.

Our personal winner for weld removal are flap discs. Fast, efficient and producing a nicer surface quality. Having the choice between angled and flat version gives you perfect control about the grinding width. They also have the longest service life.

_____________________________________________

PRODUCTS

_____________________________________________________

RELATED VIDEOS & LINKS

_____________________________________________________

SOCIAL MEDIA

MUSIC

Grinding Discs are the most aggressive and remove lots and lots of material in a short period of time. However, they are usually very loud, vibrate a lot and leave plenty of spots and marks around the weld.

Fibre Discs are the intermediate product. They are not quite as aggressive, but still fast when removing weld seams and leave a nicer surface that needs less clean up.

Be aware though that the grinding area is somewhat wider.

Our personal winner for weld removal are flap discs. Fast, efficient and producing a nicer surface quality. Having the choice between angled and flat version gives you perfect control about the grinding width. They also have the longest service life.

_____________________________________________

PRODUCTS

_____________________________________________________

RELATED VIDEOS & LINKS

_____________________________________________________

SOCIAL MEDIA

MUSIC

Комментарии

0:06:11

0:06:11

0:30:42

0:30:42

0:03:52

0:03:52

0:01:20

0:01:20

0:00:46

0:00:46

0:00:20

0:00:20

0:00:12

0:00:12

0:00:51

0:00:51

0:21:38

0:21:38

0:13:29

0:13:29

0:01:39

0:01:39

0:05:09

0:05:09

0:02:02

0:02:02

0:00:59

0:00:59

0:12:17

0:12:17

0:01:36

0:01:36

0:13:14

0:13:14

0:58:10

0:58:10

0:00:39

0:00:39

0:16:57

0:16:57

0:02:01

0:02:01

0:00:32

0:00:32

0:00:52

0:00:52

0:03:09

0:03:09