filmov

tv

Print-Wave Metal Casting: Aluminium Mug

Показать описание

In this video, I did a test cast of a mug using the "Print Wave Metal Casting" method.

Originally, I wanted to cast it in copper, but since I didn't have an investment in stock that can withstand the heat of copper, I cast it in aluminum instead.

Originally, I wanted to cast it in copper, but since I didn't have an investment in stock that can withstand the heat of copper, I cast it in aluminum instead.

Print-Wave Metal Casting: Aluminium Mug

NO WASTE Resin Vase and Tray

One of my most favorite practical 3D prints. Professional grade sound diffusers.

Semi Automatic Screen Printing Machine | Made In India

🌊🚤 Don’t you just love the motion of the ocean? Boat size matters when the waves toss you around....

Snake gets a taste of electric #snake #electric #shock #shorts #shorts2023 #crazy #lol

Metal Printer | Metal 3D Printer | Digital Metal Printer in India

Crazy tick removal? Or fake?

Gomexus Golden Saltwater Trolling Reel #shorts #sharkfishing #offshorefishing #saltwaterfishing

Curve marking on aluminium products------Jinan Wave Label Economic & Trade CO.,Ltd

The bombing power of the slingshot steel ball is super powerful#slingshot #shooting #studio

The Surgery To Reveal More Teeth 😨

POV: you’re 6’9” 400 pounds and booked the middle seat

Do you want to better your life? #philippines #angelescity #expat #pampanga #travelvlog

If You Lost Your Tongue 🤔

3D Printing 6ft Tall Façade Panels

Who needs this?

Smear Vaseline on your Glasses and WATCH WHAT HAPPENS💥(Mind Blowing)🤯

Trying this trend at 37 weeks pregnant #shorts

Almost 3 Years As A condo Owner in Miami Beach.. This is pretty normal on a Monday in South Beach

New sand casting,sand casting, metal smelting

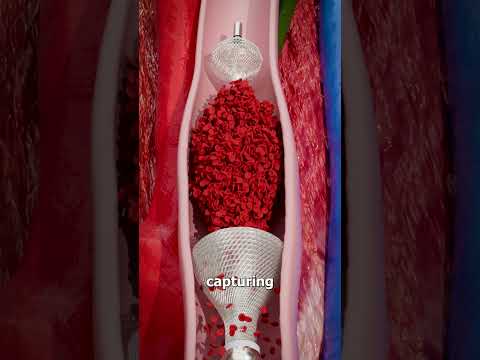

Removing Blood Clots with Vacuum 😨

The WD-40 Effect | Acrylic Pour Painting

Spanish Bridge in Ocho Rios Www.islanddreamtour.com

Комментарии

0:08:11

0:08:11

0:00:34

0:00:34

0:00:35

0:00:35

0:00:14

0:00:14

0:00:15

0:00:15

0:00:21

0:00:21

0:00:51

0:00:51

0:00:11

0:00:11

0:00:14

0:00:14

0:00:10

0:00:10

0:00:22

0:00:22

0:00:20

0:00:20

0:00:18

0:00:18

0:00:16

0:00:16

0:00:25

0:00:25

0:00:16

0:00:16

0:00:15

0:00:15

0:01:32

0:01:32

0:00:13

0:00:13

0:00:26

0:00:26

0:00:12

0:00:12

0:00:29

0:00:29

0:02:52

0:02:52

0:00:22

0:00:22