filmov

tv

New Software Interface Between KUKA and Siemens Benefits Customers

Показать описание

In the town of Neu-Ulm, Germany, specialist machine builder Wieland Anlangentechnik focuses on creating optimal solutions for their customers, both large and small. By combining the flexibility of robotics with the precision of machine tools, the company delivers cost-effective solutions for processing particularly large and geometrically complex components.

Using a KUKA KR 180 QUANTEC with foundry protection, integrated directly with Siemens software in KUK.mxAutomation, the process is easy to control. With this system, the machine operator can run the cell and the robot via the Sinumerik Operate interface -- creating a beneficial situation in which operators that are well-versed in the popular Siemens control environment have a shorter training and learning period.

This new interface between the KUKA and Siemens control systems enables the operation of a robot cell just like the machine tool itself and it can be completely programmed in the Siemens 840D Solution Line, which both the operators and programmers are familiar with.

New Software Interface Between KUKA and Siemens Benefits Customers

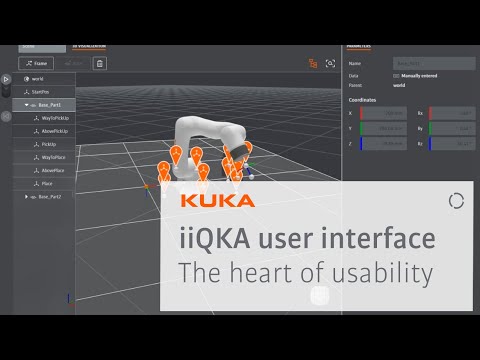

Webinar: iiQKA user interface

KUKA UserTech - Simplified interaction with your robot #robot #programming #kuka

KUKA Robot Standard Interface Communication Configuration

KUKA RSI Control of KUKA robot, with Visual Components digital twin example 2

C3 Bridge Interface to control Kuka robots

KUKA.HMI Easy Webinar

KUKA Nordic Webinar KSS 8.6 & 8. 7

ME10 : Implementation of MATLAB Interface for KUKA

New operating system for the LBR Med KUKA Sunrise.OS Med

Kuka Sunrise Toolbox, virtual teach pendant

Configuration SYS Tags between KUKA Robot and PLC

KUKA Interface Platform

KUKA Ecosystem: The new robot operating system with developer ecosystem

A new mobile platform ENG Webinar by KUKA Nordic

Webinar KUKA EasyHMI

KUKA UI

Using Visual Components to control the a KUKA robot with RSI

KUKA RSI server

Using Visual Components to control the a KUKA robot with RSI example 2

Medical Robotics Software Option Package for LBR Med: KUKA Sunrise.PreciseHandGuiding Med

mxAutomation setup

Getting started with my.KUKA

KUKA RSI Control of KUKA robot, with Visual Components digital twin

Комментарии

0:03:36

0:03:36

0:33:15

0:33:15

0:02:34

0:02:34

0:05:39

0:05:39

0:00:17

0:00:17

0:00:24

0:00:24

0:55:08

0:55:08

0:17:28

0:17:28

0:03:00

0:03:00

0:04:19

0:04:19

0:00:48

0:00:48

0:02:04

0:02:04

0:16:08

0:16:08

0:03:07

0:03:07

0:24:36

0:24:36

0:08:58

0:08:58

0:02:56

0:02:56

0:00:48

0:00:48

0:00:31

0:00:31

0:01:01

0:01:01

0:03:37

0:03:37

0:04:04

0:04:04

0:01:54

0:01:54

0:00:17

0:00:17