filmov

tv

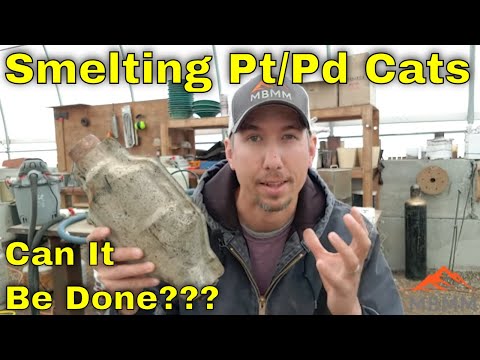

Smelting Platinum/Palladium Catalytic Converters For PGMs..... Success???

Показать описание

AFFILIATE LINKS

What's an affiliate link? If you use our link to buy something, MBMM gets a small percentage of the money you spend. This DOES NOT mean you will spend more money using our link, you will spend the SAME AMOUNT of money while also supporting a small business and channel.

Complete Smelting Kits:

Fluxes:

Smelting Supplies:

Furnace Building Supplies:

Underground Mining Equipment:

Filming Equipment:

For more info please email or call:

Phone: 360-595-4445

Smelting Catalytic Converters, Platinum, Palladium, & Rhodium

Smelting Platinum/Palladium Catalytic Converters For PGMs..... Success???

Smelting Catalytic Converters for Platinum, Palladium & Rhodium PGM

Palladium From Catalytic Converters In 6 Minutes

Smelting Platinum From Catalytic Converters #smelting #platinum #catalyticconverter

Can Platinum & Palladium Be Smelted From Catalytic Converters? Urban Mining Platinum and PGMs!

Platinum Recovery From Catalytic Converters

How To Extract Platinum From Catalytic Converter (platinum recovery),

Extract Palladium and platinum from car CATALYTIC CONVERTERS

Platinum Catalytic Converter Smelting

Melted recovery mixture of platinum group metals from 100 catalytic converters. #autorecycling

Platinum and Palladium catalyst oxidises Propane.

PALLADIUM RHODIUM PLATINUM EXTRACTION

How Much Is A Catalytic Converter Worth? Scrap Recycling Guide

How to extract precious metals and make money from catalytic converters! #shorts

First step to Processing catalytic converters for platinum and other precious metals

Precious Metal From Catalytic Converter

Recycling Factories – Precious Metals Extraction of Catalytic Converters

PGM extraction from a Catalytic Converter.

Platinum-Palladium-Rhodium (PdRhodium) Fire Enrichment #foryou #refining

The daily work of refining platinum, palladium and rhodium.

#shorts catalytic converter inside gold ✨️

The Devils Forge & “Platinum” 🔥 #shorts #refining #forge

Precious metals in a Catalytic Converter #carexhaust #catalyticconverter #rhodium #palladium #cars

Комментарии

0:12:37

0:12:37

0:33:39

0:33:39

0:00:58

0:00:58

0:05:39

0:05:39

0:00:55

0:00:55

0:23:52

0:23:52

0:00:28

0:00:28

0:07:36

0:07:36

0:13:52

0:13:52

0:00:55

0:00:55

0:00:10

0:00:10

0:02:23

0:02:23

0:09:27

0:09:27

0:05:44

0:05:44

0:00:52

0:00:52

0:06:27

0:06:27

0:20:53

0:20:53

0:05:19

0:05:19

0:02:17

0:02:17

0:00:13

0:00:13

0:00:16

0:00:16

0:00:15

0:00:15

0:01:01

0:01:01

0:00:38

0:00:38