filmov

tv

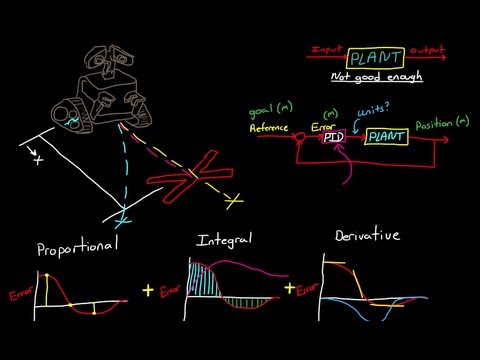

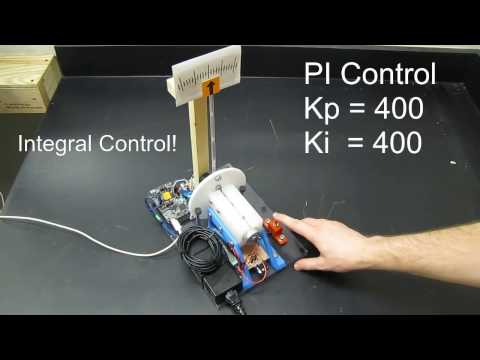

PID Theory and Practice Part 3, P,I,PI Control of Speed

Показать описание

Overview of PID controllers starting with basic definitions through using PI / PD controllers for controlling a (simulated) DC motor

Part 1

Definitions, basic terms

Part 2

Simple DC motor model

Part 3

P, I, and PI control of motor velocity

Part 4

Practical considerations

Simple tuning rules

Part 5

PI, PD, and PID control of motor position

Psuedo Code for a PID controller - Typically only the P and I parts or P and D parts would be used.

Const F32 P_Gain = 1; // Gain for proportional controller

Const F32 I_Gain = .1; // Gain for integral controller

Const F32 D_Gain = .01 // Gain for derivative controller

Const F32 Filter_Const = .25 // Filter constant for filtering input to derivative controller

// minimum value = 0, maximum value = 1

F32 P_Control; // output of proportional controller

F32 I_Control; // output of integral controller

F32 D_Control; // output of integral controller

F32 Filter_Out; // output of filter

F32 Filter_Out_Prev // previous output of thefilter - use to get delta change

Const F32 Target_Value = 100; // target set point for controller

F32 Measured_Value; // measured plant output

F32 Error_Value; // difference between desired and measured plant output.

F32 PID_Out; // final controller output value

F32 Loop_Time // time for one control loop - could be a constant or a measured value

Measured_Value = input(); // get A/D reading -- convert units if necessary

Error_Value = Target_Value -- Measured_Value;

P_Control = P_Gain * Error_Value;

I_Control = I_Control + I_Gain * Error_Value * Loop_Time; // integrate error * gain*delta time

// If you leave out the loop time, you can adjust the gain value to somewhat compensate

Filter_Out_Prev = Filter_Out; // save previous value

Filter_Out = Filter_Const*Error_Value + (1-Filter_Constant)* Filter_Out;

// take a portion of the new input and a portion of the old value to average out over several samples

// simulate a first order exponential filter.

D_Control = D_Gain * (Filter_Out - Filter_Out_Previous) / Loop_Time; // derivative output based on filtered value

PID_Out = P_Control + I_Control + D_Control; // Final output

Part 1

Definitions, basic terms

Part 2

Simple DC motor model

Part 3

P, I, and PI control of motor velocity

Part 4

Practical considerations

Simple tuning rules

Part 5

PI, PD, and PID control of motor position

Psuedo Code for a PID controller - Typically only the P and I parts or P and D parts would be used.

Const F32 P_Gain = 1; // Gain for proportional controller

Const F32 I_Gain = .1; // Gain for integral controller

Const F32 D_Gain = .01 // Gain for derivative controller

Const F32 Filter_Const = .25 // Filter constant for filtering input to derivative controller

// minimum value = 0, maximum value = 1

F32 P_Control; // output of proportional controller

F32 I_Control; // output of integral controller

F32 D_Control; // output of integral controller

F32 Filter_Out; // output of filter

F32 Filter_Out_Prev // previous output of thefilter - use to get delta change

Const F32 Target_Value = 100; // target set point for controller

F32 Measured_Value; // measured plant output

F32 Error_Value; // difference between desired and measured plant output.

F32 PID_Out; // final controller output value

F32 Loop_Time // time for one control loop - could be a constant or a measured value

Measured_Value = input(); // get A/D reading -- convert units if necessary

Error_Value = Target_Value -- Measured_Value;

P_Control = P_Gain * Error_Value;

I_Control = I_Control + I_Gain * Error_Value * Loop_Time; // integrate error * gain*delta time

// If you leave out the loop time, you can adjust the gain value to somewhat compensate

Filter_Out_Prev = Filter_Out; // save previous value

Filter_Out = Filter_Const*Error_Value + (1-Filter_Constant)* Filter_Out;

// take a portion of the new input and a portion of the old value to average out over several samples

// simulate a first order exponential filter.

D_Control = D_Gain * (Filter_Out - Filter_Out_Previous) / Loop_Time; // derivative output based on filtered value

PID_Out = P_Control + I_Control + D_Control; // Final output

Комментарии

0:11:51

0:11:51

0:12:19

0:12:19

0:13:15

0:13:15

0:11:41

0:11:41

0:13:28

0:13:28

0:07:44

0:07:44

0:09:59

0:09:59

0:11:42

0:11:42

0:06:25

0:06:25

0:01:00

0:01:00

0:13:10

0:13:10

0:15:03

0:15:03

0:24:56

0:24:56

0:02:58

0:02:58

0:00:09

0:00:09

0:26:11

0:26:11

0:01:01

0:01:01

0:00:13

0:00:13

0:04:22

0:04:22

0:34:06

0:34:06

0:07:36

0:07:36

0:12:14

0:12:14

0:22:19

0:22:19

0:33:01

0:33:01