filmov

tv

How to Screen Print: Printing Two Color Plastisol Heat Transfer Sheets

Показать описание

This has to be by far one of our most requested videos yet. In this video Ryan Moor takes you through all the steps from start to finish on how to accomplish a multi color plastisol heat transfer. Enjoy!

00:00 Introduction

00:14 Why Heat Transfers?

01:45 What You'll Need

02:14 Making a Screen

03:24 Creating Film Positives

04:33 Setting Up the Job

08:59 Printing the Top Coat

10:58 Flash Curing

12:29 Printing the Underbase

13:47 Curing

16:11 Production

19:19 Heat Pressing

21:47 Finishing Up

#ryonet #poweringtheprint

RELATED PRODUCTS:

CONNECT WITH RYONET

CONNECT ON SOCIAL

PROMO CODE

ABOUT SCREENPRINTING.COM

00:00 Introduction

00:14 Why Heat Transfers?

01:45 What You'll Need

02:14 Making a Screen

03:24 Creating Film Positives

04:33 Setting Up the Job

08:59 Printing the Top Coat

10:58 Flash Curing

12:29 Printing the Underbase

13:47 Curing

16:11 Production

19:19 Heat Pressing

21:47 Finishing Up

#ryonet #poweringtheprint

RELATED PRODUCTS:

CONNECT WITH RYONET

CONNECT ON SOCIAL

PROMO CODE

ABOUT SCREENPRINTING.COM

Screen Print Your Own T-Shirt: Step by Step Tutorial

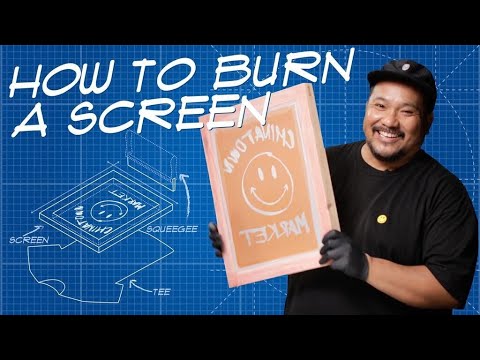

How To Make A Screen For Screen Printing | THE BLUEPRINT

The Basics of Screen Printing | Screen Printing Tutorial

How to SCREENPRINT Your Art | My silkscreen print process

Screen Printing from Start to Finish | Part 1 Artwork basics with Kittl.

How To Screen Print a Shirt (& more) with a Cricut! Full Screen Printing Tutorial, Start to Fini...

How To Screen Print T-Shirts (Screen Printing For Beginners) The ULTIMATE Guide

Here's Everything You Need To Start Screen Printing?

here’s an old print process video!! #art #artanddesignschool #printmaking #zeldatotk

Screen Printing for beginners. ❤️ #screenprinting #beginners #tips #shorts

How to screen print t-shirts at home (DIY method) | CharliMarieTV

How To Screen Print -Step by Step process

How I Screen Print Without Photo Emulsion!

EQUIPMENT YOU NEED TO START SCREEN PRINTING | RIGHT AWAY!!

Screen Print with me ✸ HOW I BURN A SCREEN ✸ Printing at home ✸

How to Create Screen Printing transfers for Beginners (Step-By-Step Tutorial)

Screen Printing Marilyn Monroe #screenprinting #upcycledclothing #diy #streetwear

SCREEN PRINT AT HOME FOR UNDER $50

✅How to make Puff Print Hoodies using HTV and Heat Press! #heattransfervinyl #clothingbrand #howto

Screen Printing Halftones. #screenprint #screenprinting #shorts

Screen Printing A to Z ।। Step by Step Process of Screen Printing

How to Screen Print at home [ Pushing vs Pulling a Squeegee ] Screen Printing Tips and tricks

Screen Print Your Own T-shirts // How-To | I Like To Make Stuff

How to Print Like Warhol | Tate

Комментарии

0:14:13

0:14:13

0:05:53

0:05:53

0:02:21

0:02:21

0:11:45

0:11:45

0:15:46

0:15:46

0:13:59

0:13:59

0:20:02

0:20:02

0:15:26

0:15:26

0:00:54

0:00:54

0:01:00

0:01:00

0:07:07

0:07:07

0:08:17

0:08:17

0:18:32

0:18:32

0:09:54

0:09:54

0:05:07

0:05:07

0:12:02

0:12:02

0:00:16

0:00:16

0:12:59

0:12:59

0:00:50

0:00:50

0:00:15

0:00:15

0:04:12

0:04:12

0:08:45

0:08:45

0:05:25

0:05:25

0:05:30

0:05:30