filmov

tv

The YASA Story - Axial Flux Motors: The Future Of Electric Vehicle Propulsion

Показать описание

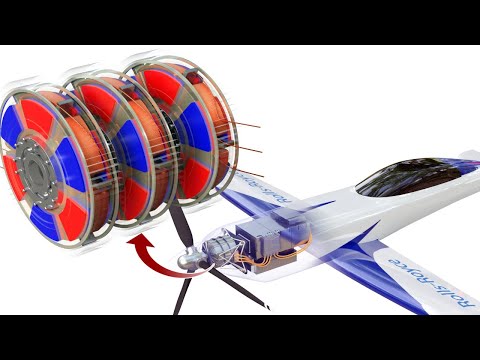

The YASA Axial Flux Motor is an ultra high performance electric vehicle motor, capable of taking you further & faster, due to it's unmatched weight, size and power density, compared to current electric cars on the road.

And it is a reality today.

This is the YASA Story.

It started in 2005, when YASA CTO & Founder, Tim Woolmer, during his PHD, began investigating the electric motor and it's suitability for the electric vehicle industry.

This led him down the Axial Flux Motor route, as these has known benefits with regard to torque density.

Axial Flux motors were identified as potential EV motor topologies in the 1800's, but despite the potential for weight reduction, it was the difficulty in manufacturing that limited its commercial viability.

Despite the challenges, Tim began researching the Axial Flux Motor in combination with new materials, in the hope of finding a solution.

When compared with a radial flux motor, which is about 400 newton metres, weighing 50kg with 25-30 kg of iron, the Axial Flux Motor is similar in diameter, but about 1/6 of the length, about 4 x the torque density.

That gives opportunities to package motors in new places in vehicles, and reduce weight, mass & therefore cost.

The YASA Axial topology and the removal of 60-80% of the stators mass removing the heavy iron yoke, and as many other metals as possible, enables up to 480 bhp, from a 24kg motor, which occupies much less space than a radial equivalent.

One of the breakthroughs in Tims PHD was the new topology called the YASA Machine (Yokeless And Segmented Armature).

As this topology was investigated, it was discovered that it had significant advantages in weight, size & mass. These savings gave the YASA motor a unique benefit, with improved efficiencies.

Less weight = less material = less energy therefore less Co2 emissions in both driving and manufacturing.

The YASA Axial Flux technology has come a long way since the journey started in 2005. We are looking to make electric cars as light and as sustainable as possible, by reducing their mass, reducing their materials and maximising their efficiency

We've seen huge change in the last 10 years and we're going to see even more change in the vehicles we drive.

Our relationship with Mercedes Benz is a powerful one, because it enables YASA to evolve & develop our products, whilst also working with Mercedes to scale up the production

The YASA Axial Flux motor will create totally new possibilities for car designers; possibilities that we are now developing with Mercedes-Benz AMG and that will change automotive development forever.

This is the story of the ultra high performance YASA Axial Flux motor and we're only just getting started!

Follow us on social:

#yasa #yasaaxialfluxmotor #axialflux #mercedes #mercedesbenz #mercedesamg #electricfuture #electricvehicles #electriccars #electricmotors

And it is a reality today.

This is the YASA Story.

It started in 2005, when YASA CTO & Founder, Tim Woolmer, during his PHD, began investigating the electric motor and it's suitability for the electric vehicle industry.

This led him down the Axial Flux Motor route, as these has known benefits with regard to torque density.

Axial Flux motors were identified as potential EV motor topologies in the 1800's, but despite the potential for weight reduction, it was the difficulty in manufacturing that limited its commercial viability.

Despite the challenges, Tim began researching the Axial Flux Motor in combination with new materials, in the hope of finding a solution.

When compared with a radial flux motor, which is about 400 newton metres, weighing 50kg with 25-30 kg of iron, the Axial Flux Motor is similar in diameter, but about 1/6 of the length, about 4 x the torque density.

That gives opportunities to package motors in new places in vehicles, and reduce weight, mass & therefore cost.

The YASA Axial topology and the removal of 60-80% of the stators mass removing the heavy iron yoke, and as many other metals as possible, enables up to 480 bhp, from a 24kg motor, which occupies much less space than a radial equivalent.

One of the breakthroughs in Tims PHD was the new topology called the YASA Machine (Yokeless And Segmented Armature).

As this topology was investigated, it was discovered that it had significant advantages in weight, size & mass. These savings gave the YASA motor a unique benefit, with improved efficiencies.

Less weight = less material = less energy therefore less Co2 emissions in both driving and manufacturing.

The YASA Axial Flux technology has come a long way since the journey started in 2005. We are looking to make electric cars as light and as sustainable as possible, by reducing their mass, reducing their materials and maximising their efficiency

We've seen huge change in the last 10 years and we're going to see even more change in the vehicles we drive.

Our relationship with Mercedes Benz is a powerful one, because it enables YASA to evolve & develop our products, whilst also working with Mercedes to scale up the production

The YASA Axial Flux motor will create totally new possibilities for car designers; possibilities that we are now developing with Mercedes-Benz AMG and that will change automotive development forever.

This is the story of the ultra high performance YASA Axial Flux motor and we're only just getting started!

Follow us on social:

#yasa #yasaaxialfluxmotor #axialflux #mercedes #mercedesbenz #mercedesamg #electricfuture #electricvehicles #electriccars #electricmotors

Комментарии

0:13:31

0:13:31

0:02:27

0:02:27

0:02:06

0:02:06

0:02:27

0:02:27

0:06:39

0:06:39

0:01:32

0:01:32

0:02:27

0:02:27

0:19:41

0:19:41

0:01:07

0:01:07

0:14:33

0:14:33

0:12:03

0:12:03

0:02:39

0:02:39

0:05:43

0:05:43

0:12:16

0:12:16

0:07:32

0:07:32

0:00:20

0:00:20

0:11:10

0:11:10

0:06:52

0:06:52

0:03:17

0:03:17

0:02:27

0:02:27

0:08:04

0:08:04

0:09:39

0:09:39

0:05:53

0:05:53

0:00:25

0:00:25