filmov

tv

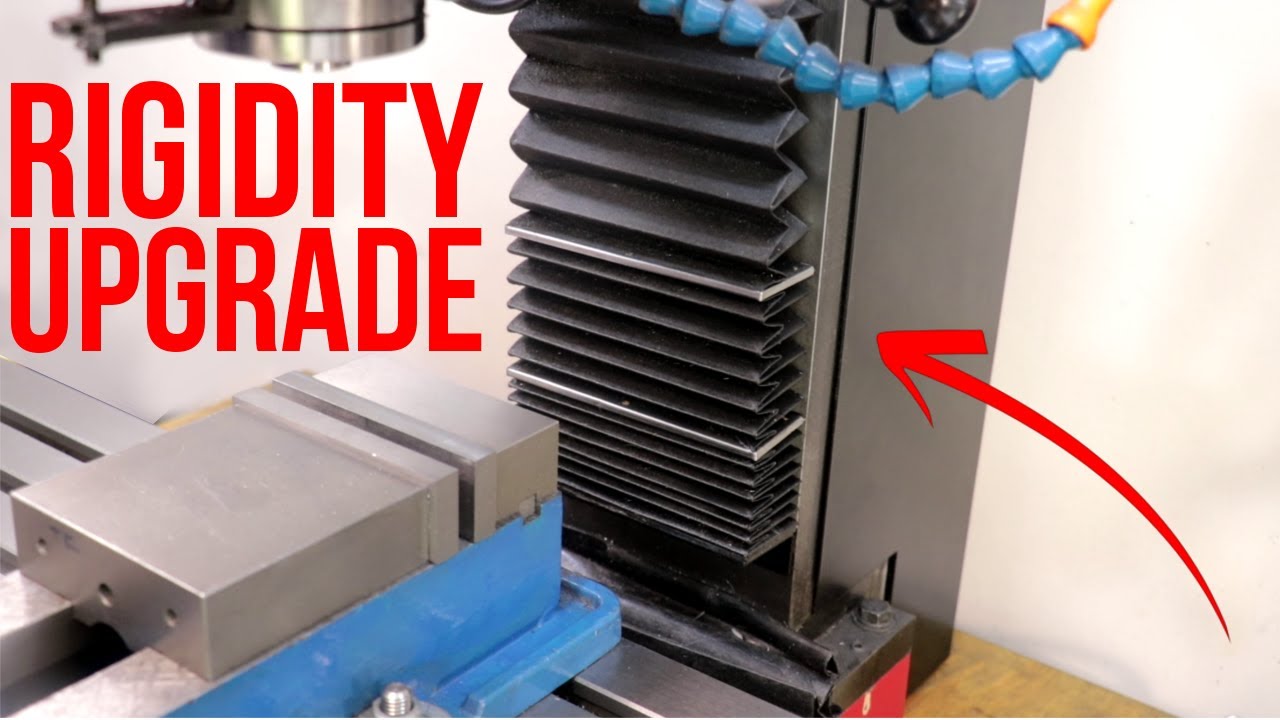

Milling Machine Rigidity Upgrade - Stiffening Plate

Показать описание

G'day everyone,

In this video I will be trying to stiffen the milling machine in order to increase the rigidity and dampen the vibrations, which are especially bad when doing deep cuts in steel. The fact or the matter is that the milling machine just doesn't have enough mass, and the overall mass of the column leaves a lot to be desired.

In this video I will be mounting a stiffening plate to the back of the mill column to increase the rigidity. I hope you find this video useful, especially if you are looking at improving your own mini mill.

#millingmachine #machining #diy

Timestamps

0:00 Introduction

0:36 - Vibration Issues

2:00 - Steel Plate

4:14 - Drilling The mounting Holes

4:57 - Drilling, Counterboring And Mounting

7:24 - Testing And Before/After Comparison

10 More Mini Lathe Mods And Upgrades - 2022

Milling Machine Rigidity Upgrade - Stiffening Plate

Upgrade! How to give your MaxNC CNC Y Axis +10 rigidity for very little money.

Mini Lathe Headstock Rigidity Upgrade

Checking Stiffness and Backlash on my DIY CNC Mill!

How Rigid Can We Make the MaxNC CNC Mini-Mill? The Answer is Very!

Small Milling Machine Improvements - PM-728VT

Fixing the weak column of a harbor freight mini mill

I manually machined these billet parts on a 64 year old milling machine

SIEG X2 mini mill update

I Filled My Milling Machine With Lead, Cast Iron and Epoxy Granite. Here Is Why

RIGCNC- Aluminum Upgrade Rigidity Test

Filling my milling machine with epoxy sand to increase rigidity.

Why Would You Ever Use CONVENTIONAL Milling??? | Climb vs Conventional

Improving Rigidity on a RongFu Clone Milling Machine

Upgrading my Homemade CNC

Milling Machine Upgrades - New Vise & DRO Installation

Mini Mill (Harbor Freight, Sieg X2, etc.) Igaging DRO & Column Stiffener

Rigid Mini Lathe Upgrade | Tapered Roller Bearings, Solid Tool Post, Brass Gib Strips Mod

The Ultimate Mini Mill - The Best Upgrades I Made To It

High rigidity milling machine is working

Upgrading The $200 CNC Machine

7 Easy Milling Machine Improvements and Mods

Simple Hints to Get Better Performance out of your Mill.

Комментарии

0:14:46

0:14:46

0:09:17

0:09:17

0:18:30

0:18:30

0:12:39

0:12:39

0:08:03

0:08:03

0:06:43

0:06:43

0:25:54

0:25:54

0:03:22

0:03:22

0:11:55

0:11:55

0:02:07

0:02:07

0:20:21

0:20:21

0:07:57

0:07:57

0:10:47

0:10:47

0:03:37

0:03:37

0:28:40

0:28:40

0:12:25

0:12:25

0:13:31

0:13:31

0:11:41

0:11:41

0:12:37

0:12:37

0:19:43

0:19:43

0:00:07

0:00:07

0:11:47

0:11:47

0:10:58

0:10:58

0:02:53

0:02:53