filmov

tv

A Closer Look: Idle Air Control (IAC) Valves

Показать описание

******

Located on the throttle body of fuel-injected engines, the idle air control valve or IAC valve works with the vehicle’s ECU to electrically regulate airflow to ensure smooth idling.

According to our research, more than 70 million vehicles model years 1995 through 2005 on the road today have an IAC that will need to be replaced soon.

Common failures include:

* General solenoid failure from everyday use

* Wear and tear from corrosion

* Clogged valve

Common symptoms of failure include:

* Stalling when the engine is idling

* Rough or unsteady idling

* Extreme RPM drops during slowdown

To provide a superior replacement, we manufacture a line of Idle Air Control Valves at our certified facilities in Greenville, South Carolina, and Reynosa, Mexico. A key aspect of our process is our load testing, which tests our IAC valves at greater than normal force to make sure each actuator delivers a greater force than actual load.

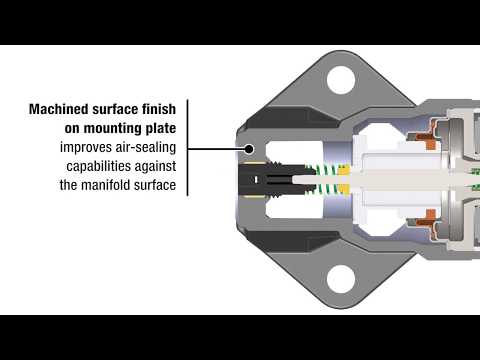

Let’s take a closer look at some other key features:

* Precision-machined solenoid components generate magnetic force to actuate the plunger

* High-temp polyester coating on the solenoid coil wire ensures proper function during cyclic exposure to elevated temperatures

* Precision-machined housing ensures proper air flow to engine during changing load requirements

* Machined surface finish on mounting plate improves air-sealing capabilities against the manifold surface

* Anodized aluminum housing resists corrosion better than regular passivation treatment.

For proof, we subjected our IACs to a salt-fogging test against the OE, which is prone to corrosion due to harsh environmental conditions. As you can see from the test results, our thicker and more robust anodized coating withstands corrosion better than the OE.

0:02:08

0:02:08

0:00:09

0:00:09

0:17:45

0:17:45

0:00:41

0:00:41

0:07:41

0:07:41

0:25:25

0:25:25

0:12:48

0:12:48

0:04:37

0:04:37

0:01:30

0:01:30

0:02:35

0:02:35

0:02:47

0:02:47

0:30:15

0:30:15

0:09:01

0:09:01

0:16:23

0:16:23

0:02:20

0:02:20

0:14:34

0:14:34

0:06:55

0:06:55

0:07:37

0:07:37

0:04:38

0:04:38

0:00:16

0:00:16

0:13:52

0:13:52

0:01:00

0:01:00

0:03:41

0:03:41