filmov

tv

HOW TO DIY: MEASURE LS PUSHROD LENGTH-CHEAP & EASY!

Показать описание

STEP BY STEP-HOW TO-MEASURE LS PUSHROD LENGTH-WHY DO YOU NEED TO MEASURE? WHEN DO YOU NEED TO MEASURE? WHAT CHANGES THE REQUIRED LENGTH? HOW CAN I MEASURE AT HOME WITH NO SPECIAL TOOLS? WHAT CAN GO WRONG IF THE LENGTH IS WRONG? CHECK OUT THIS 10-MINUTE TECH (ACTUALLY 11 MIN OR SO) ON HOW YOU CAN QUICKLY AND EASILY (YOUR FIRST TIME) MEASURE FOR PROPER PUSHROD LENGTH ON YOUR LS!

HOW TO DIY: MEASURE LS PUSHROD LENGTH-CHEAP & EASY!

How to Measure LS Engine Pushrod Length (In 7 Minutes)

Shop Tech: Do you really need to Deck your Ls block?? Lets find out.

DIY how to surface your LS block at home Resurfacing a LS block for new head gaskets #lsx #trending

How to Measure LS Pushrod Length (very easy) - Tech Tip Tuesday

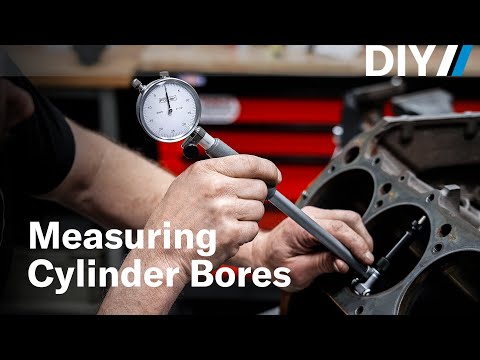

Measuring cylinder bores using a dial bore gauge | DIY

LS Engine Priming The Easy Way - $15 Tool

DIY CYLINDER BORE CHECK: How to measure OUT OF ROUND, TAPER, and REBORE size - STEP BY STEP GUIDE

Measuring Torque Converter Air Gap on your LS Swap #car #lsswap #measure #howto #tutorial

Priming a GM LS engine with a DIY bucket luber

DIY LS Engine Mounts Under $40 | How To Build LS Engine Mounts for V8 swap.

Honing For The Home Engine Builder

TWO EASY METHODS FOR MEASURING LS PUSHROD LENGTH!! - TURBO 5.3 LS pt 9

TECH TIP! How to measure your LS engine for proper pushrod length

Measure motor mounts accurately between engine and frame #hotrod #automobile #ls #tricks

How To Measure Steering Wheel For Custom Leather Cover | LeatherSeats.com | LS Tech Tips

Before we start assembling our LS, let's get some measurements first. #ls2 lsx #ls #engine #reb...

How to make ls swap motor mounts diy Porsche 944 or any car

How to check pre-load on Chevy LS lifters. #shorts

2 ways to measure your bearing clearance! #LS #5.3 #shorts #rebuild

DIY $3 LS Valve Spring Compressor

Completely Balancing a LS Motor Build!

How to build a LS 383 from a 5.3 part 7 (measuring for pushrod length)

How to LS Swap your CLASSIC CAR for Dummies!

Комментарии

0:11:33

0:11:33

0:08:11

0:08:11

0:02:01

0:02:01

0:00:55

0:00:55

0:09:53

0:09:53

0:09:11

0:09:11

0:09:04

0:09:04

0:10:52

0:10:52

0:00:59

0:00:59

0:04:13

0:04:13

0:08:47

0:08:47

0:08:16

0:08:16

0:11:48

0:11:48

0:07:51

0:07:51

0:00:47

0:00:47

0:02:19

0:02:19

0:00:15

0:00:15

0:06:49

0:06:49

0:00:13

0:00:13

0:01:01

0:01:01

0:05:00

0:05:00

0:00:11

0:00:11

0:17:28

0:17:28

0:11:26

0:11:26