filmov

tv

Bruschi – Zinc die casting process for multiple sectors

Показать описание

Bruschi, an Italian company for hot chamber die casting, displays its vertical integrated zinc die casting process, that can be applied to different sectors: automotive, electromechanical, electronics, white goods, building, professional coffee machines, locking systems and more. This diversity is Bruschi strength and has lead the company to export both in Europe and oversea, with its new subsidiary Bruschi USA.

Thanks to over 70 years of expertize in the metal industry, Bruschi optimized its zinc die casting process in a vertical integrated approach that covers every step of product creation, starting from customers’ ideas to create the most functional products for our clients. This includes Co-Design, Simulation, Rapid Prototyping, Tool Design, Tool Construction and Maintenance, Die Casting & Mass Production, Mechanical Operations, Finishing, Painting and Chrome, Assembly and Shipping.

Every phase in the production of zamak components is carefully planned by Bruschi technicians in close collaboration with customers’ team: this co-design approach helps make the most of zinc alloys qualities.

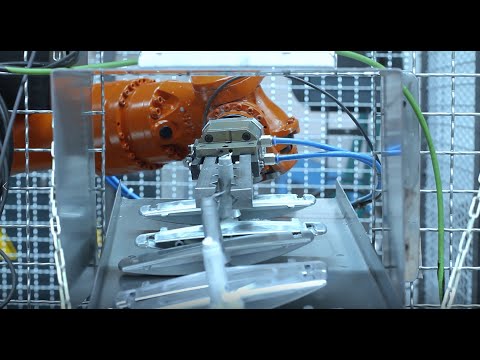

All the tools needed for high pressure die casting are designed and constructed in Bruschi plants: from molds to peripheral devices, such as trimming tools and deburring machines, but also industrial automations for machining and assembly.

These automations are built in Bruschi Mechanics, where the final mechanical operations and assembly take place, before proceeding with finishing, chroming and painting.

At the end of zinc die casting process, Bruschi ships finished products directly to its customers, to guarantee its clients an all-in-one solution.

To learn more about Bruschi, check out our website:

Thanks to over 70 years of expertize in the metal industry, Bruschi optimized its zinc die casting process in a vertical integrated approach that covers every step of product creation, starting from customers’ ideas to create the most functional products for our clients. This includes Co-Design, Simulation, Rapid Prototyping, Tool Design, Tool Construction and Maintenance, Die Casting & Mass Production, Mechanical Operations, Finishing, Painting and Chrome, Assembly and Shipping.

Every phase in the production of zamak components is carefully planned by Bruschi technicians in close collaboration with customers’ team: this co-design approach helps make the most of zinc alloys qualities.

All the tools needed for high pressure die casting are designed and constructed in Bruschi plants: from molds to peripheral devices, such as trimming tools and deburring machines, but also industrial automations for machining and assembly.

These automations are built in Bruschi Mechanics, where the final mechanical operations and assembly take place, before proceeding with finishing, chroming and painting.

At the end of zinc die casting process, Bruschi ships finished products directly to its customers, to guarantee its clients an all-in-one solution.

To learn more about Bruschi, check out our website:

0:02:08

0:02:08

0:01:12

0:01:12

0:04:32

0:04:32

0:01:33

0:01:33

0:03:15

0:03:15

0:02:35

0:02:35

0:01:29

0:01:29

0:02:12

0:02:12

0:00:19

0:00:19

0:00:16

0:00:16

0:00:33

0:00:33

0:04:32

0:04:32

0:00:17

0:00:17

0:00:11

0:00:11

0:00:16

0:00:16

0:00:38

0:00:38

0:00:43

0:00:43

0:03:00

0:03:00

0:00:08

0:00:08

0:01:12

0:01:12

0:01:22

0:01:22

0:01:24

0:01:24

0:00:21

0:00:21

0:04:26

0:04:26