filmov

tv

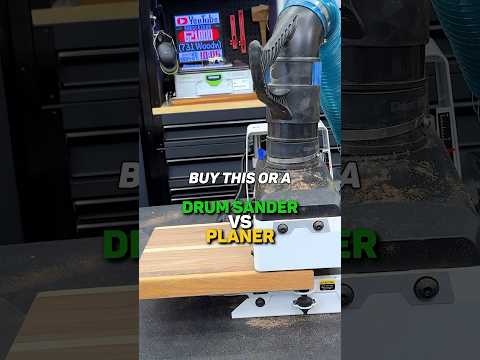

Can a Single Tool Change your Entire Workflow?

Показать описание

In this video we got to play with a new, more professional CNC. The X-Carve Pro by inventables...and we decided to answer one of the most common questions we get whenever we use our CNC to make templates which is. "Why don't you just cut the finished shape on the CNC" - after some experimentation I think we found a pretty good answer to that question and had some realizations along the way.

#woodworking #CNC # Templates

FOLLOW

Can a Single Tool Change your Entire Workflow?

VMC MACHINE TOOL CHANGE || VMC MACHINE TOLL CHANGE KAISE KARE .

The RapidChange Automatic Tool Change Magazine Story / Affordable ATC for everyone.

Will change the way you use your tools every single day#shorts

High Speed DIY ATC CNC Router Tool Change with Auto Air Assist Retraction

'Smart Tools That Change the Way You Live' #shorts #shortsfeed #youtubeshortsvideo

CNC Router One Handed Tool Change and Spindle LED Ring

New tech that could change the world 🤯 #CES2025 #CES #engineering

25 MUST HAVE EDC GEAR for 2025 That Will Change Your Life!

This is My Favourite Knipex Tool! Change My Mind! #shorts

Understanding Tool Change Command

V1 vs. V2 Magnetic IDEX Tool Change Demo. Follow the White Rabbit 🐇

Easy Tool Change - Ryobi R18MT-0 ONE+ 18V Cordless Multi-tool - #shorts

Anet A8 Dual Extruder using single nozzle AND single motor. Toolchange

Automatic tool change wood lathe cnc

2 Incredible Tools Change Small Shops

This All-in-One Tool Will Change Your Life! #shorts #tools #allinone #usefultools

Rotate your phone and see magic Automatic Tool Change in slow motion CNC milling #cnc #atc

Lifehacks That Will CHANGE Your Life! P7 #diy #tools #adamrose #tips

Quick automatic tool change! The six-axis machining center is working!

Apple Self Service Repair Tool Changes The Game.... #Shorts

Geneva - Tool Change Mechanism of ATC in VMC #cnc #vmc #machining #shorts #ytshorts #tools #cam #cad

Changing the Game Efficient CNC Milling Tool Changes #shorts

How to Command a Safe Tool Change Position to Avoid Fixtures and Rotaries – Haas Tip of the Day

Комментарии

0:21:25

0:21:25

0:00:31

0:00:31

0:03:14

0:03:14

0:00:19

0:00:19

0:00:33

0:00:33

0:00:18

0:00:18

0:00:35

0:00:35

0:00:59

0:00:59

0:21:40

0:21:40

0:00:15

0:00:15

0:08:03

0:08:03

0:00:16

0:00:16

0:00:30

0:00:30

0:00:22

0:00:22

0:00:16

0:00:16

0:00:51

0:00:51

0:00:58

0:00:58

0:00:11

0:00:11

0:01:01

0:01:01

0:00:13

0:00:13

0:00:50

0:00:50

0:00:15

0:00:15

0:00:27

0:00:27

0:05:44

0:05:44