filmov

tv

First Article Inspection Report Beginners' Guide

Показать описание

What is a First Article?

First article is the first item which is manufactured using the same production processes as mass production by any subcontracted factory or supplier.

So that the client can validate how the supplier is capable of producing parts, and assemblies that meet all engineering and design requirements on a mass.

What is a First Article Inspection?

Once a new or revised part is manufactured on the first production run, it is necessary to ensure that all requirements (such as the specific drawings and specifications) have been met by inspecting a random sample of the first production run. This is called "first article inspection (FAI)".

In First Article Inspection, many organizations inspect every single dimension and specification of this sample against the drawing, as part of the detailed verification of production results versus product design, before the manufacturing process begins.

This is a First Article Inspection Process. First Article Inspection is conducted after the first production run.

In First Article Inspection, all measured results must conform to their requirements. For example: Requirement #1 is 5.000 inches in diameter with

a plus or minus tolerance of 0.01. Result #1 is 5.005. The result has conformed to the requirement.

What is a First Article Inspection Report?

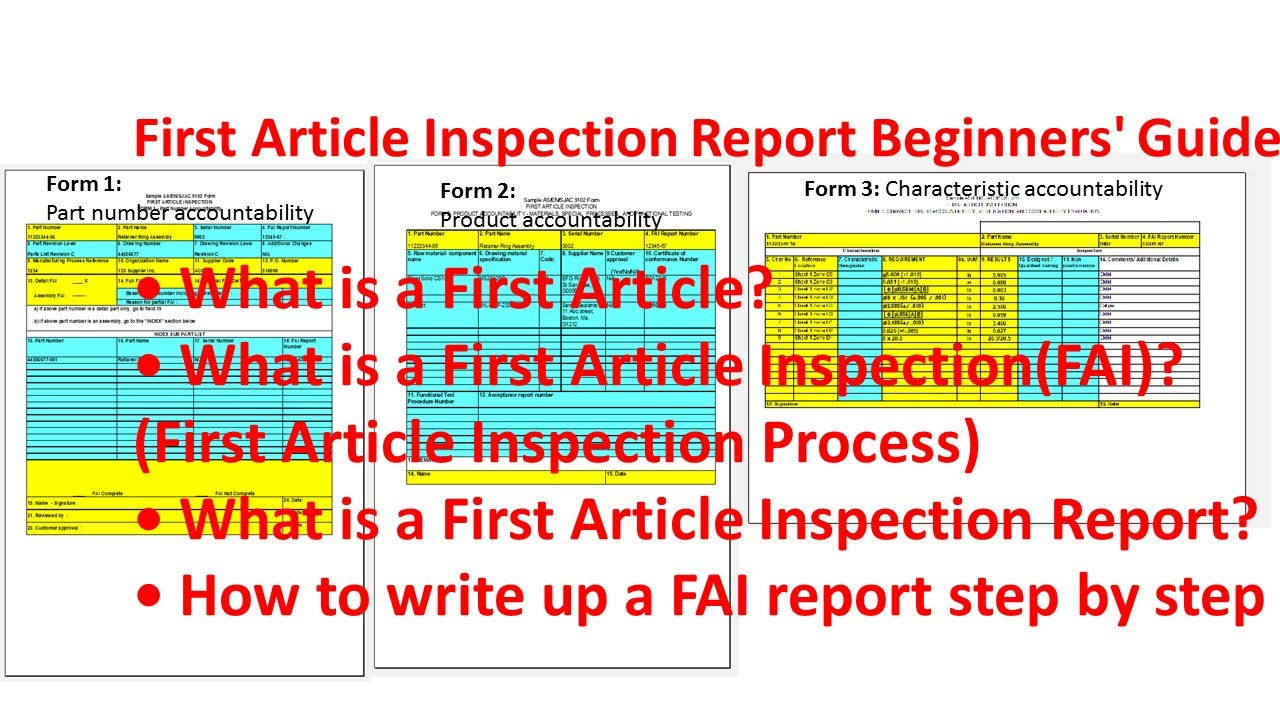

To validate that a product has been manufactured to the correct specification, First Article Inspection Report (FAIR) consists of 3 parts (Form 1:Part number accountability, Form 2: Product accountability and Form 3: Characteristic accountability ) plus ballooned drawing):

How to write up a First Aritcle Inspection Report step by step.

Form 1:Part number accountability is used to summarize the part of the article that is being first inspected (FAI part) and associated sub-assemblies or detail parts.

Form 2: Product accountability is used for all raw materials, specifications, processes and functional tests defined as a design requirement.

Form 3: Characteristic accountability is used to summarize actual specific design characteristics such as dimensions, tolerances, drawing notes, etc. as well as actual measurement results of the FAI parts for every design characteristic on the drawing.

Balloon Drawing (also called Bubble Drawing) is a necessary element of a First Article Inspection Report package to support Form 3 and to verify every design characteristic requirement. In this drawing, each design characteristic has its own uniquely numbered balloon. This number needs to match with the characteristics numbers on Form 3 for traceability.

Please download the First Article Inspection Report Input Guide (FREE & EASY edition) from our web page:

Комментарии

0:13:49

0:13:49

0:09:43

0:09:43

0:03:12

0:03:12

0:01:37

0:01:37

0:54:20

0:54:20

0:02:21

0:02:21

0:02:56

0:02:56

0:01:00

0:01:00

0:01:00

0:01:00

0:19:24

0:19:24

0:02:43

0:02:43

0:21:20

0:21:20

0:03:01

0:03:01

0:01:59

0:01:59

0:00:11

0:00:11

0:02:01

0:02:01

0:00:11

0:00:11

0:13:39

0:13:39

0:04:33

0:04:33

0:35:24

0:35:24

0:00:21

0:00:21

0:27:25

0:27:25

0:03:51

0:03:51

0:01:34

0:01:34